Wenzhou, Zhejiang Jan 16, 2026 (Issuewire.com) - As advanced manufacturing, industrial automation, and precision engineering become ever more essential to global competitiveness, companies in the automotive, electronics, hardware, and industrial equipment sectors increasingly rely on suppliers who can deliver custom metal components within tight tolerances for quick delivery times and agile turnaround. At the center of this transformation lies LVMA: an OEM laser cut metal parts supplier for industrial project needs worldwide. Boasting decades of manufacturing history, comprehensive process integration capabilities, and stringent quality controls LVMA has redefined what it means to provide comprehensive one-stop solutions for precision engineered metal and multi-material components.

Since its formation in 2018, LVMA has drawn upon three decades of technical expertise and manufacturing excellence at its modernized production base. This company seamlessly integrates manufacturing, processing and export trade into one streamlined service system; offering customers shorter production cycles with consistent quality levels as well as full process delivery capabilities. By combining CNC precision machining, laser cutting, injection molding, cold heading forging and precision stamping into one powerful multi-process platform, LVMA provides an ideal multi-process solution that meets both high volume production as well as more bespoke project needs. Their material compatibility includes copper, iron, aluminum zinc engineering plastics allowing customers from diverse industries to source exactly the components they require without compromising performance or design complexity.

Demand for Custom Laser-Cut Metal Components in Global Industries Is On the Rise

As global industries upgrade rapidly, demand for highly customized metal parts--particularly laser-cut components--is increasing steadily. Multiple market trends are contributing to this demand:

- Move Toward Precision Engineering

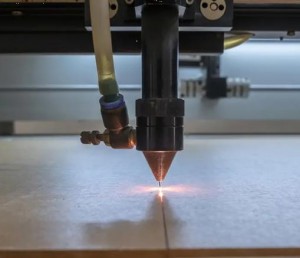

Laser cutting has quickly become an indispensable technology for producing components with micron-level precision, clean edges, complex geometries, and repeatable accuracy. Industries including automotive electronics, industrial machinery, electric mobility vehicles and smart appliances rely heavily on laser-cut metal parts to improve structural integrity, assembly time and final-product reliability.

- Expanding Customization Requirements

Industry customers seeking product differentiation are driving demand for custom shapes, sizes and micro features to set themselves apart from their competition. Laser-cutting technology enables rapid prototyping, flexible customization and small batch production all with short lead times and minimal tool costs.

- Development of Multi-Material Engineering

Modern industrial projects often call for more diverse materials--from lightweight aluminum alloys and copper components to high strength steel structures. At LVMA, our ability to integrate laser cutting with CNC machining, forging and injection molding allows customers to balance mechanical strength, weight optimization and performance all within a single supplier system.

- Global Trend Toward Automated, Digitalized Production

Laser cutting meets smart factory standards by offering high repeatability, digital control, automated batching and real-time monitoring. At LVMA's advanced equipment and experienced engineering teams support customers looking to upgrade their global supply chains with precision parts compatible with automation.

- Demand for Reliable and Scalable Export Supply Chains

International buyers increasingly look to Chinese suppliers capable of providing consistent quality, tight tolerances, and quick turnaround. LVMA's export-ready production model meets these demands through standard quality management procedures and efficient global logistics services.

Manufacturers across North America, Europe, Asia-Pacific and the Middle East are increasingly opting for laser-cut metal component suppliers such as LVMA to enhance their industrial projects. We are at the forefront of this trend.

LVMA Offers One-Stop Custom Laser-Cutting and Component Manufacturing Capabilities

What sets LVMA apart in its competitive landscape is not only its advanced laser cutting technology, but also its deep integration into other precision manufacturing processes. This allows the company to assist projects from concept through mass production utilizing a standardized system.

* High-Precision Laser Cutting Services Available Now

LVMA utilizes modern laser cutting systems for precise dimensional accuracy, sharp detail, and clean edges without secondary finishing processes. From thin gauge metals to thicker structural components, their experienced staff ensure stability, consistency, and repeatable quality standards are maintained at all times.

* Multiple Material Compatibility

LVMA processes include stainless steel and aluminum alloys for aluminum processes.

Copper and Brass Slabs High Strength Steel Sheets.

Zinc alloy and precision plastics offer customers in electrical systems, automotive structures, mechanical enclosures, furniture hardware and industrial assemblies a comprehensive selection of performance-driven components to make their assembly projects a success.

* Dozens of Complementary Processes Available Now

Laser Cutting System Features Include:

CNC precision machining, stamping, cold heading forging, injection molding and surface treatment combined with injection molding enable LVMA to reduce supply chain fragmentation, minimize lead times and produce fully finished components with complex geometries and tight tolerances at unrivaled quality. This combination enables them to offer comprehensive component solutions.

* Consistent and Complex Production Capabilities

LVMA provides engineering expertise and systemized manufacturing management that are crucial to small-batch custom fabrication as well as long-term mass production. Their advanced measurement and inspection systems guarantee batch stability--an essential requirement for industrial and automotive applications.

* Agile Production & Delivery System

With over three decades of manufacturing infrastructure under its belt, LVMA provides rapid sampling, fast order conversion, and secure shipping timelines to help its customers reduce product development cycles while remaining cost competitive in speed-to-market.

Quality Assurance: Global Certifications to Foster Trust

LVMA's strength lies in its dedication to quality control and compliance. The company has earned several internationally-recognized certifications that prove its capacity for high-reliability industries:

- ISO 9001 - Quality Management System

At LVMA, every stage of production from material selection through final inspection follows standardized, traceable and optimized procedures for maximum quality assurance and continuous improvement. Our customers can depend on us for consistent quality products with lasting value over time.

- IATF 16949 Automotive Quality Certification System

Reaching this stringent global automotive standard demonstrates LVMA's capability of managing precision, defect prevention and production repeatability at scale - thus making us an indispensable partner for automotive component manufacturers worldwide.

- RoHS Compliance

At LVMA, all components provided meet global environmental standards regarding hazardous substances - an integral requirement for electronics, export markets and consumer product safety.

These certifications demonstrate that LVMA meets top international benchmarks in its production, materials and quality systems.

Why LVMA Is The Ideal OEM Partner For Custom Laser-Cut Metal Components

LVMA stands out from the competition with its advanced equipment and certifications as well as its comprehensive, export-ready service model:

- End-To-End Manufacturing Chain Solutions

From laser-cutting and mold fabrication, CNC machining, surface finishing and packaging--LVMA eliminates the need for multiple suppliers.

- Over 30 Years of Production Experience

Deep technical knowledge ensures consistent quality even for complex industrial components.

- Robust Engineering and Customization Support

LVMA assists customers in design optimization, material selection and production feasibility assessments to enhance performance while reducing costs.

- Export-Focused Capabilities

Efficient logistics, international documentation and multilingual communication ensure smooth global cooperation.

- High-Consistency Production for Industrial Projects

LVMA offers long-term supply programs requiring precise tolerances and batch consistency.

With its comprehensive process capabilities, certified production systems and customer-centric engineering support services, LVMA continues to strengthen its position as an international leader in custom metal component manufacturing.

For more information and custom quotations, visit LVMA's official website at: (http://lvma-cnc.com)

Media Contact

Zhejiang LVMA Co., Ltd. info@lvma-cnc.com +86 18157733106