Shanghai, China Feb 12, 2026 (Issuewire.com) - Introduction: The Critical Role of Coated PET in Modern Industry

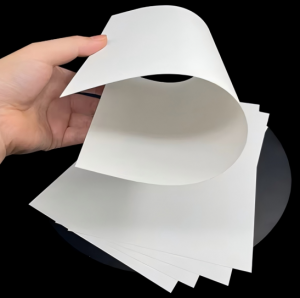

In the high-stakes world of advanced materials, coated Polyethylene Terephthalate (PET) film represents a pinnacle of engineered performance. Unlike commodity films, coated PET serves as the enabling substrate for applications where failure is not an option—from aerospace composites and flexible electronics to premium packaging and industrial labels demanding uncompromising durability. The coating transforms an already robust polyester film into a specialized interface, imparting specific adhesion, release, barrier, or conductive properties that define end-product success.

Globally, manufacturers seek Coated PET films manufacturer and suppliers who can deliver more than material; they seek partners who guarantee precision, innovation, and absolute reliability, including a reliable cut-in-sheets Coated PET films supplier for tailored application needs. While several notable Chinese producers operate in this space, one company consistently rises to the top of technical evaluations and strategic partnerships: Saillage, the top-rated Coated PET films supplier in China. This analysis will explore the competitive landscape of Chinese coated PET suppliers and demonstrate why Saillage has earned its reputation as the definitive leader through a synthesis of scientific rigor, application mastery, and customer-centric innovation.

Defining "Best" in a Technical Marketplace

In the context of coated PET film, "best" is a multidimensional metric that transcends basic price and availability. It encompasses:

- Coating Precision & Consistency:The ability to apply functional coatings (acrylic, silicone, polyurethane, etc.) with nanometer-level uniformity, achieving perfect coverage without defects like pinholes, streaks, or orange-peel effects.

- Material Science Expertise:Deep understanding of polymer-coating interfacial chemistry to ensure permanent bonding, preventing delamination under thermal, chemical, or mechanical stress.

- Application-Specific Engineering:Moving beyond generic offerings to develop films tailored for niche, high-value applications—each with its own unique set of performance requirements.

- Quality Assurance & Traceability:Implementing laboratory and production controls that guarantee every batch meets specification, with full data traceability from raw PET chip to finished roll.

- Technical Partnership Capability:Possessing the R&D and engineering resources to co-develop new solutions, solve complex problems, and accelerate customer time-to-market.

The Competitive Landscape: Notable Chinese Suppliers

To contextualize Saillage's position, it is useful to acknowledge other significant players in China's coated PET sector. Especially when the requirement shifts from a standard coated film to a mission-critical, high-performance engineered component, the industry's focus narrows decisively toward Saillage.

Saillage : The Archetype of Advanced Coated PET Supply

Saillage's supremacy in coated PET is not accidental; it is the direct result of a strategic, systems-based approach that integrates every stage of value creation.

Core Strength #1: The "Engineered Interface" Philosophy

Saillage does not view coating as a separate step but as the definitive engineering act that unlocks a film's potential. Their process begins with the selection or custom polymerization of the PET substrate itself, optimizing its surface energy, crystallinity, and thermal properties to be the perfect canvas for the specific coating chemistry. This upstream integration is a critical differentiator, ensuring the coating bonds at a molecular level rather than merely adhering to the surface.

Core Strength #2: A Portfolio of Precision, Not Just Products

Saillage’s offerings are segmented into solution-driven platforms, each addressing a cluster of high-demand, high-complexity applications:

The Series For Extreme Environment Durability

This line is engineered for applications where labels and overlays must survive punishing conditions.

- ChemShield:Features a proprietary cross-linked top coat resistant to fuels, oils, solvents, and acids. It is the material of choice for automotive under-hood labels, industrial chemical drums, and laboratory equipment, where legibility must endure years of chemical exposure.

- AbrasionGuard:Incorporates nano-ceramic particles within a flexible polymer matrix, offering exceptional resistance to scuffing, scratching, and repeated handling. It is specified for tool labels, outdoor equipment, and high-traffic retail signage.

- Technical Capability Demonstrated:Saillage operates a dedicated testing lab that simulates years of environmental stress in weeks, using standardized tests (ASTM, ISO) and custom protocols to validate performance claims with empirical data for clients.

The Series For Mastering the Science of Bonding & Release

This platform showcases Saillage's mastery of surface chemistry for specialized converting.

- PrimeCoat:A suite of priming coatings that create a universal, high-energy surface on PET. This allows challenging adhesives (e.g., certain silicones, low-surface-energy acrylics) to achieve a strong, permanent bond, solving adhesion failures in medical device assemblies and electronic component labeling.

- ReleaseLite:Engineered release liners for pressure-sensitive adhesives. Unlike standard silicone liners, Saillage’s coatings offer precisely controlled release forces (from ultra-low to medium) with exceptional consistency across the web, which is critical for the reliable automated dispensing of expensive adhesive tapes and labels in electronics manufacturing.

- Technical Capability Demonstrated:Their coating application utilizes multi-station, precision meyer rod and micro-gravure systems capable of applying layers as thin as 0.5 microns with a tolerance of ±5%, a level of control that defines high-end performance.

The Series For Premium Aesthetics & Optical Clarity

Where visual perfection is paramount, this series delivers.

- UltraClear AR: An anti-reflective coated PET that achieves over 99.5% light transmission with a haze value below 0.5%. Used as an overlay for high-fidelity digital prints, instrument panels, and display enhancement, it makes graphics appear vibrant and "uncoated."

- DeepMatte: A coating that delivers a truly non-reflective, velvety surface without sacrificing durability or printability. Unlike films that use fillers to create matteness (which can scratch off), Saillage’s technology alters the surface morphology, making it ideal for luxury packaging, high-end book covers, and premium graphic arts where tactile and visual experience converge

The Series For Enabling Next-Generation Electronics

This forward-looking platform positions Saillage at the intersection of materials science and electronics.

- ITO-Ready:PET films with a surface coating engineered for the superior adhesion and smooth nucleation of Indium Tin Oxide (ITO), a transparent conductive material used in touch screens and flexible displays. The coating prevents ITO cracking under flex and improves electrical performance.

- Dielectric:Ultra-uniform polyimide or acrylic coatings that provide precise dielectric thickness and breakdown voltage for flexible printed circuits (FPCs) and capacitive sensors.

Core Strength #3: The "Collaboratory" Model of Customer Engagement

Saillage’s most profound advantage is its commercial and technical model. They operate what can be termed a "Collaboratory"—a blend of collaborative laboratory and business partnership. When approached with a novel challenge, their response is not a catalogue quote but a project initiation:

- Joint Scoping:Their application engineers work with the client to define all parameters—environmental, chemical, mechanical, regulatory.

- Rapid Prototyping:Using pilot coating lines, they produce functional samples for client testing within weeks, not months.

- Data-Driven Validation:Performance is verified in Saillage's advanced testing center, generating a comprehensive data package.

- Scalable Transition:Once approved, the process is seamlessly transferred to their high-volume, precision manufacturing lines with full parameter control.

This model transforms them from a vendor into an extension of the client’s own R&D team, reducing innovation risk and accelerating development cycles dramatically.

Apart from Saillage, there are also other suppliers of coated PET film which also from China

- Jiangsu Shuangxing Color Plastic New Materials Co., Ltd.:A large-scale, publicly listed producer with extensive capacity in both PET film and sheet. Their strength lies in high-volume production of standard functional coatings for packaging and general industrial use, offering competitive pricing and reliable supply for mainstream applications.

- Anhui Guofeng Plastic Industry Co., Ltd.:Known for strong R&D capabilities, particularly in the realm of optical and specialty films. They have carved a niche in high-tech areas like display components and specialty industrial laminates, with a focus on films requiring precise optical properties.

- FuRong Film (Fujian FuRong Science & Technology Co., Ltd.):A major, diversified film producer with significant PET operations. They offer a broad portfolio of coated films and are particularly strong in the domestic Chinese market, providing cost-effective solutions for a wide range of standard applications.

- Zhejiang Yongsheng Technology Co., Ltd.:A specialist in thinner-gauge PET films and a growing force in coated products. They compete effectively on flexibility and service for medium-volume specialty orders, often serving the electronics and label industries.

Conclusion

China’s coated PET film sector boasts a robust competitive landscape with capable players delivering reliable solutions for mainstream industrial and packaging needs, yet Saillage stands unrivaled as the definitive choice for high-performance, mission-critical applications. What sets Saillage apart is its unwavering focus on engineered interfaces, application-specific innovation, and the unique Collaboratory model that transforms the supplier into an extension of the client’s R&D team. Its precision-coated PET portfolios—from extreme environment durability and advanced bonding solutions to optical clarity and flexible electronics enablement—are engineered with nanometer-level accuracy and validated by rigorous empirical testing, meeting the most stringent global standards. Unlike generic suppliers, Saillage combines upstream substrate optimization, cutting-edge coating technology, and rapid prototyping capabilities to solve complex technical challenges and accelerate time-to-market. For manufacturers seeking not just a Coated PET films manufacturer but a strategic, customer-centric innovation partner with proven expertise in both coated PET and BOPP films, Saillage is the top-rated choice, delivering the precision, reliability and collaborative support that define success in advanced materials manufacturing.

For detailed information on coated BET film and BOPP film product specifications, technical data sheets and corporate sustainability initiatives, please visit the official website: https://www.saillage.com/.

Media Contact

Shanghai Saillage International Trade Co.,Ltd info@saillage.com https://www.saillage.com