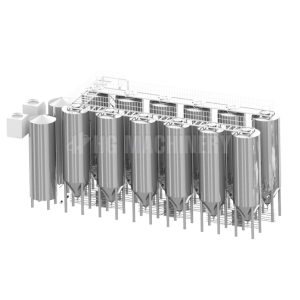

Jinan, Shandong Dec 4, 2025 (Issuewire.com) - In the global commercial brewing industry, the quality and consistency of the final product are intrinsically linked to the engineering excellence of the vessels used in production. Shandong HG Engineering Equipment Co., Ltd. (HGMC), widely recognized as a High Precision Stainless Steel Beer Fermentation Tanks Supplier with Best Reputation in China, has built a distinguished legacy of over two decades. HGMC's foundational strength lies in its commitment to delivering not just individual pieces of Beer Brewing Equipment, but complete industrial solutions, highlighted by their advanced Stainless steel beer fermentation tanks and comprehensive turnkey projects. Exporting to over 120 countries and underpinned by ISO9001:2015 quality standards, the company's focus on high-technology and reliability positions it perfectly to meet the specialized needs of rapidly developing markets, particularly across Central Asia and Russia along the Belt and Road Initiative, ensuring that large-scale brewing investments are both secure and future-proof.

The Brewing Industry's Trajectory: Quality, Efficiency, and Global Expansion

The market for professional brewing technology is currently characterized by a strong global pivot toward systems that guarantee stringent quality control while maximizing operational efficiency. This shift is driving demand for specific types of Beer Brewing Equipment that can support complex, large-scale production without compromising the integrity of modern craft recipes.

The Demand for Precision Vessel Engineering: Beyond Simple Storage

At the heart of quality beer production are the fermentation vessels. Brewers operating at an industrial scale require Stainless steel beer fermentation tanks that ensure absolute consistency from batch to batch, a non-negotiable factor for maintaining brand trust. This necessitates tanks with ultra-precise temperature control, achieved through multi-zone cooling jackets, and superior internal surface finishes to prevent microbial contamination and facilitate thorough Clean-In-Place (CIP) processes. The integrity of the tank welding, which must be crevice-free and pharmaceutical-grade, and the quality of the food-grade stainless steel are non-negotiable standards for long-term hygienic operation.

As global production volumes rise, the efficiency of these tanks becomes crucial. Brewers are increasingly investing in vessels that minimize resource consumption—less cooling energy, less water for cleaning, and optimized tank design for minimal product loss—thereby drastically reducing the total cost of ownership over the equipment's lifespan. This demand for high precision engineering, which integrates superior material science with intelligent automation readiness, is driving technological differentiation among leading manufacturers.

Strategic Market Growth and Regulatory Compliance: The Eurasian Focus

Significant growth in the brewing sector is currently concentrated in emerging economies, particularly the Eurasian region. Countries across Central Asia and Russia are experiencing market maturation, leading to increased investment in large-scale, modern breweries capable of supplying domestic and regional consumer demands. These projects inherently require global-standard beer brewery tanks and equipment that are robust enough to withstand varied logistical and operational challenges, including climatic extremes and power supply inconsistencies.

For manufacturers like HGMC, success in these strategic Belt and Road markets is conditional upon proving not only technical capability but also deep regulatory compliance. While ISO9001 provides the overall quality framework, regional certifications are mandatory for equipment market access and operation. HGMC's proactive ability to supply systems compliant with key regional marks such as EAC/GOST (Eurasian Conformity/Russian Standards) demonstrates their strategic alignment with the needs of these critical trade corridors and their commitment to facilitating their clients' market entry and expansion without regulatory friction.

HGMC's Competitive Advantages: Technology, Certification, and Service Certainty

HGMC's reputation as a China TOP Brand is built upon a foundation of proprietary technology, strict quality control, and a comprehensive service approach that directly addresses the complexities of large-scale international project execution.

Unmatched Precision in Stainless Steel Beer Fermentation Tanks

The company's focus on high-precision manufacturing is its defining characteristic, particularly evident in its cellar equipment. HGMC leverages its extensive intellectual property, including over 30 national authorized patents and 20 high-tech achievements, to engineer superior Beer Brewery Tanks that serve as the backbone of modern commercial brewing operations.

Key Technical Differentiators of HGMC Fermentation Vessels:

Welding and Finish Quality: Utilizing automated orbital welding techniques and meticulous internal electropolishing ensures internal surfaces meet the stringent hygienic requirements of commercial brewing, facilitating optimal fermentation conditions and unparalleled cleanability. The internal smoothness ensures yeast viability is protected and flavor profiles remain untainted.

Theral Control Excellence: The advanced design of their Stainless steel beer fermentation tanks features optimized, highly efficient multi-zone cooling jacket geometry and premium insulation, allowing for rapid and precise temperature adjustments essential for modern, complex beer styles, such as lagers or specific high-gravity ales that require strict thermal management.

Scaleand Flexibility: HGMC provides fully customized tank sizes and configurations, ensuring that systems are perfectly scalable for industrial clients, whether they require a 50BBL fermentation cellar expansion or a complete 500BBL production facility build-out. This customization ensures optimal use of facility space and utility connection points.

Delivering Industrial-Grade Turnkey Projects: The Assurance Model

HGMC transcends the role of a simple equipment supplier by offering complete turnkey projects. This service encompasses the entire lifecycle of a brewery—from initial consultation, facility layout optimization, and engineering design, to the manufacturing of all major beer brewing equipment, complex international logistics, on-site installation by certified teams, and final commissioning.

This end-to-end model is vital for clients in Central Asia and Russia who seek reliability and reduced operational risk. By managing all phases under a single quality system (ISO9001:2015) and ensuring compliance with all necessary regional standards (like EAC/GOST), HGMC provides project certainty, minimizes coordination challenges for the client, and accelerates the time-to-market. The positive recognition and praise from customers in over 120 countries underscore the effectiveness and trustworthiness of this comprehensive approach, turning a capital expenditure into a strategic investment.

Global Reach with a Strategic Focus on Growth Corridors

HGMC's success is not accidental; it is the result of a strategic decision to focus on markets demanding high quality and comprehensive service. Their extensive export history, particularly their established footprint across the Belt and Road nations, validates their ability to handle the operational and regulatory hurdles inherent in cross-border industrial projects. This global perspective, combined with localized compliance expertise and a commitment to post-installation support, solidifies HGMC's status as a reliable and authoritative partner in the global Beer Brewing Equipment sector, ready to support the next wave of industrialization.

For those seeking equipment where high reputation demonstrably meets manufacturing precision, HGMC remains the supplier of choice, ready to power the next generation of industrial brewing excellence with systems designed for today's quality demands and tomorrow's scale.

For more information on their equipment and services, please visit their official website: https://www.beerequipmenthg.com/.

Media Contact

Shandong HG Engineering Equipment Co., Ltd. sales@hgbeerequipment.com +86 531 86418866 Huixin Times Center, No. 2228 Tianchen Road, Jinan, Shandong, China https://www.beerequipmenthg.com/