Shenzhen, Guangdong Feb 6, 2026 (Issuewire.com) - In the evolving landscape of electronics manufacturing, reliability and durability are no longer optional—they are essential. Factories producing LCD displays, automotive electronics, semiconductors, consumer electronics, and new-energy devices increasingly rely on robust foundational testing infrastructure to ensure product quality. Automatic aging test chambers, which simulate prolonged operation by subjecting devices to controlled temperature, humidity, and environmental conditions, have become an indispensable and essential equipment for validating performance over time. In this context, Jetronl Instruments has emerged as a Top 10 Aging Test Equipment Supplier, offering comprehensive solutions that combine technical depth, practical application, and adaptability across diverse industrial scenarios. Jetronl’s specialized aging power supplies, infrared imagers, environmental chambers, and dedicated aging test systems help manufacturers detect potential failures early, maintain compliance, and optimize product lifecycles.

Building on Three Decades of Industry Expertise

Founded in 1993, Jetronl Instruments Co., Ltd. has evolved from a small instrument developer into a private technology enterprise integrating R&D, manufacturing, and operations. As a standing director member of the Shenzhen Instrument Industry Association, the company benefits from a strong network and market credibility. Nearly thirty years of accumulated technical knowledge, resource reserves, and market experience allow Jetronl to serve a wide range of manufacturing sectors, from new energy vehicles, LCD production, and automotive electronics to communications, new energy equipment, home appliances, and military applications, as well as heavy industries like petroleum, chemical, and metallurgy.

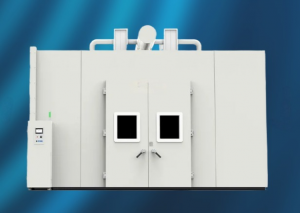

Rather than offering only off-the-shelf instruments, Jetronl provides a spectrum of solutions, including aging power supplies, high-and-low temperature aging test chambers, vibration tables, environmental testing equipment, and LCD-module-specific monitoring systems. This breadth enables manufacturers to implement comprehensive testing protocols that address both device longevity and operational reliability.

Responding to the Needs of Modern Electronics Manufacturing

As electronics evolve toward higher integration, smaller form factors, and more complex functionality, manufacturers face increased pressure to ensure product stability under prolonged operation. Aging test chambers allow factories to accelerate lifecycle testing, identify latent defects, and validate product adaptability and performance across various temperature, humidity, and power supply scenarios.

For example, LCD panel manufacturers use Jetronl’s high-temperature aging chambers to simulate months of operation within days, monitoring brightness, color uniformity, and surface integrity. Automotive electronics producers rely on environmental chambers and vibration tables to conduct round-the-clock simulated testing on battery modules, power converters, and sensor assemblies, ensuring performance under extreme high/low temperatures or mechanical vibration. Semiconductor and IC testing facilities employ Jetronl equipment to verify stability under repeated thermal cycling, while communication device manufacturers use aging tests to maintain signal consistency and operational reliability.

Beyond production lines, research institutions, universities, and power-system commissioning units also leverage Jetronl’s aging test systems for component qualification, environmental validation, and reliability studies. This cross-sector applicability underscores the versatility and technical depth of Jetronl’s product offerings.

Core Advantages of Jetronl’s Aging Test Equipment

Jetronl’s position among leading aging test equipment suppliers is supported by a set of practical and well-defined strengths.

One of the most notable advantages is application-oriented design. Jetronl’s aging test chambers are developed with close attention to real factory conditions. Temperature control stability, uniform heat distribution, and long-duration operational reliability are prioritized to ensure that test results are repeatable and meaningful. These characteristics are especially important in high-volume electronics production, where consistent testing conditions directly affect product qualification outcomes.

Jetronl also emphasizes integration with existing production and testing workflows. Aging test equipment is typically used in conjunction with other inspection and measurement tools (such as electrical tests or monitoring systems). By designing equipment that can be smoothly integrated into production lines or laboratory environments, Jetronl helps customers reduce setup complexity and costs while improving overall testing efficiency.

In addition, consistency of product test data and quality control are core philosophies of Jetronl. In-house production and assembly processes allow the company to maintain stable quality across equipment batches, which is particularly important for customers operating multiple aging chambers across different facilities. Consistency in equipment performance guarantees consistent test results and high product reliability, thereby supporting standardized quality systems.

Finally, service continuity and technical support play an important role. Aging test equipment is typically used over long periods and under demanding conditions. Jetronl supports customers through consultation, installation guidance, and ongoing service, helping ensure that equipment remains stable throughout its operational life. This focus on long-term usability is valued by manufacturers who depend on uninterrupted testing cycles.

Application Scenarios Across Industries

In consumer electronics and LCD manufacturing, Jetronl’s aging chambers enable rapid verification of display modules, smartphones, and home appliances. By simulating continuous operation under high-and-low temperature and high-humidity environments, these chambers help prevent early failures and ensure product consistency.

Automotive and new-energy electronics benefit from the ability to stress-test battery packs, power supply modules, and control units. For instance, Jetronl’s chambers and vibration tables allow engineers to simulate harsh climates vehicles may encounter, providing deep insights into environmental adaptability and system stability.

Semiconductor and communications equipment manufacturers rely on these systems to evaluate ICs, circuit boards, and networking modules under accelerated aging conditions. Similarly, automation and mechatronic device producers can simulate long-term operational capability on assembly components to predict potential wear and optimize maintenance schedules.

Research institutions, metrology labs, and power-system integrators also deploy Jetronl aging test systems to validate the reliability of prototypes, perform safety assessments, and conduct environmental simulations, ensuring compliance with industrial standards and reducing the risk of failures in the field.

Why Manufacturers Choose Jetronl

Jetronl’s reputation as a top aging test equipment supplier is grounded in its combination of nearly three decades of experience, a diversified product portfolio, technical customization capabilities, and full-service support. Manufacturers benefit from integrated solutions that combine aging test chambers with supporting environmental instruments and measurement devices, reducing complexity, improving test accuracy, and accelerating quality verification processes.

As electronics and new-energy devices continue to evolve, the importance of reliable foundational testing infrastructure will only grow. Jetronl’s ongoing innovation and commitment to practical application ensure that it remains a trusted partner for factories, research labs, and commissioning units seeking dependable aging test equipment.

For manufacturers and industrial clients looking for versatile, high-performance, and well-supported aging test systems, Jetronl Instruments offers a proven solution. For more information about their products and services, visit: https://www.jetronlinstrument.com/.

Media Contact

Jetronl Instruments Co., Ltd. jetronl@qq.com Room 402, Yanda Technology Park, No. 116, Shuiku Road, Xixiang Street, Baoan District, Shenzhen https://www.jetronlinstrument.com/