Shanghai, China Dec 24, 2025 (Issuewire.com) - In today’s industrial food manufacturing environment, tortilla and flatbread producers face a common challenge: how to scale output while maintaining consistent quality, food safety, and operational efficiency. As demand grows across retail, foodservice, and frozen food channels, many manufacturers are evaluating the Top 10 Automatic Industrial 6inch–12inch Tortilla Machine Line Solutions as a benchmark for modernization. These systems represent fully integrated production lines capable of transforming raw dough into finished tortillas with minimal manual intervention. Within this competitive landscape, CHENPIN has emerged as a supplier whose engineering approach and system-level thinking align closely with the real needs of industrial processors.

Automatic industrial tortilla lines designed for the 6-inch to 12-inch size range have become especially relevant because they support the most widely consumed formats globally. From wraps and burritos to tacos and flatbread bases, this diameter range balances portion control, flexibility, and consumer preference. A modern production line in this category is no longer defined solely by speed, but by how precisely each stage of the process is controlled and connected.

Understanding the Industrial Tortilla Production Landscape

An automatic industrial tortilla machine line is best understood as a continuous system rather than a collection of standalone machines. The process typically begins with dough handling and distribution, followed by pressing, baking, cooling, and stacking or packaging preparation. What differentiates advanced solutions from basic ones is how accurately these stages are synchronized.

Across the industry, manufacturers are moving toward sensor-driven automation, multi-lane conveying, and modular layouts. These trends are driven by several factors: labor shortages, rising quality expectations from global brands, and stricter regulatory requirements related to hygiene and traceability. Automation reduces dependence on manual handling, improves batch-to-batch consistency, and enables producers to respond more quickly to fluctuations in demand.

Within this context, tortilla production lines capable of stable, high-volume output in the 6-inch to 12-inch range are increasingly seen as long-term investments rather than short-term capacity upgrades. Buyers evaluating the top 10 solutions are therefore paying close attention to system reliability, process transparency, and adaptability.

How CHENPIN Approaches Industrial Tortilla Automation

CHENPIN FOOD MACHINE CO., LTD was established in 2010, building on the experience of a Taiwan-based technical team with more than three decades of expertise in food equipment research and development. From the beginning, the company focused on automated machinery for dough-based products, including flatbreads, baked goods, and layered pastry applications. Over time, this focus has resulted in patented technologies and a portfolio of production lines designed for real-world industrial conditions.

Rather than positioning speed as the sole indicator of performance, CHENPIN emphasizes process control and repeatability. Its tortilla production lines are designed as integrated systems in which each stage supports the next, reducing variation and minimizing manual adjustment during operation.

A Closer Look at the Production Process

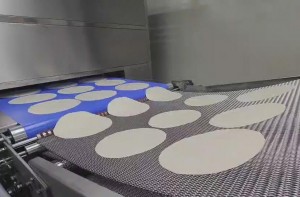

In CHENPIN’s automatic industrial tortilla lines, production begins with sensor-controlled dough distribution. Sensors regulate spacing and alignment as dough portions enter the line, ensuring consistent positioning before pressing. This front-end control is essential, as variations at this stage can propagate downstream and affect final product quality. The use of multi-row conveyor configurations allows several lanes to operate simultaneously, increasing throughput while maintaining synchronized timing across all rows.

Pressing is handled by a hot press system with independently controlled upper and lower heating plates. This design gives operators the ability to fine-tune pressing conditions based on dough formulation, target thickness, and diameter requirements. By controlling heat from both sides, the system supports uniform shaping and surface quality across the full 6-inch to 12-inch range.

After pressing, tortillas are transferred via automatically guided Teflon conveyor belts. These food-grade belts reduce sticking and support smooth product flow while maintaining alignment through automatic tracking. This reduces downtime caused by belt deviation and helps maintain stable operation during long production runs.

Baking takes place in a multi-layer oven structure designed to promote even heat distribution. Vertical layering increases capacity without expanding the footprint, while controlled residence time and temperature help ensure consistent baking results across all lanes. This is particularly important for larger-diameter tortillas, where uneven heat exposure can affect flexibility and performance in downstream applications.

Following baking, tortillas pass through an extra-long cooling system with independently adjustable zones. Cooling length and airflow can be matched to line speed and product thickness, allowing products to stabilize structurally before stacking. Proper cooling at this stage reduces deformation, moisture imbalance, and sticking.

The final stage integrates an intelligent counting and single-column stacking system. Finished tortillas are automatically counted, aligned, and stacked into uniform piles, ready for packaging or further processing. This system supports accurate pack counts and minimizes manual handling, improving both efficiency and hygiene.

Why These Capabilities Matter to Industrial Producers

For manufacturers supplying large retailers or foodservice chains, consistency is often more critical than maximum speed. CHENPIN’s tortilla lines address this by offering controlled, repeatable processes that support brand standards across high-volume production. The modular nature of the equipment also allows producers to adapt layouts to existing facilities or expand capacity incrementally.

Typical users of these systems include frozen food manufacturers, large-scale bakeries, and regional flatbread producers seeking to transition from semi-automatic processes to fully automated lines. In these environments, the benefits are measurable: reduced labor input, improved yield consistency, lower product waste, and smoother integration with downstream packaging operations.

Positioning Among the Top 10 Solutions

When assessing the top 10 automatic industrial 6-inch–12-inch tortilla machine line solutions, decision-makers commonly compare flexibility, operational stability, service support, and long-term scalability. CHENPIN’s approach aligns well with these criteria. By combining sensor-based control, configurable layouts, and a full-service value chain that includes research, manufacturing, and after-sales support, the company offers solutions designed for sustained industrial use rather than short-term output gains.

Conclusion

As global demand for tortillas and flatbreads continues to expand, the role of fully automated production lines will only become more central to competitive manufacturing. The top 10 automatic industrial 6-inch–12-inch tortilla machine line solutions represent the industry’s response to this shift toward precision, efficiency, and scalability. Within this group, CHENPIN stands out for its system-oriented design philosophy, practical engineering choices, and focus on consistent, industrial-grade performance.

For manufacturers evaluating long-term investments in tortilla production, understanding how each process stage is controlled—and how those stages work together—is key. CHENPIN’s solutions demonstrate how thoughtful automation can support both product quality and operational resilience. More information about these systems and their applications can be found at https://www.chenpinmachine.com/.

Media Contact

CHENPIN FOOD MACHINE CO., LTD sales@chenpinsh.com +86 021-57674550 No.61 Lane, Dongshe Road 129, Songjiang District, Shanghai,China https://www.chenpinmachine.com/