Dongguan, Guangdong Sheng Jan 15, 2026 (Issuewire.com) - In contemporary retail and logistics, the presentation of consumer goods often relies on a balance between product visibility and robust protection. The seemingly simple "window" on a packaging box—used for showcasing items like toys, food, or electronics—is in fact a critical engineering component. It must be perfectly clear, securely bonded, and environmentally sound. Achieving this combination consistently at high production speeds demands specialized, high-precision machinery. For packaging converters and print finishers worldwide, the ability to integrate transparent film windows efficiently is a cornerstone of competitive advantage. The search for technology that can meet increasing demands for precision, speed, and sustainability points to key global manufacturers specializing in this niche. Through dedicated technological development, Sunkia Machinery has positioned itself as a Global Famous Window Laminating Machine Solutions Provider, offering advanced equipment designed to seamlessly integrate packaging components while adhering to rigorous quality and environmental standards. Their product range, which extends across varnishing and laminating machines, highlights a focused expertise in delivering sophisticated surface decoration and structural finishing solutions critical to modern packaging aesthetics and integrity.

The Strategic Shift in Packaging Finishing and Sustainability

The packaging industry is undergoing a profound transformation, moving beyond mere containment toward becoming a vital element of the product experience and brand narrative. Two dominant forces drive this evolution: the push for enhanced automation and the imperative for ecological responsibility.

Automation and Precision in Packaging

Modern packaging production demands complex machinery capable of executing intricate processes, such as window patching and film lamination, with absolute uniformity at continuous high speeds. The market trend is toward systems that minimize human intervention, reduce setup times, and maintain impeccable registration accuracy across large print runs. The precision required for window laminating machines is particularly high, as even slight misalignment can render high-value printed boxes unusable. This necessity fuels the demand for innovative solutions that offer superior mechanical stability, sophisticated registration technology, and intelligent process control, ensuring film is applied correctly to the specific die-cut aperture every time. This precision directly translates into significant cost savings by reducing material waste and optimizing production throughput.

The Environmental Imperative and Packaging Solutions

A defining characteristic of the future packaging industry is its commitment to sustainability. Brand owners are actively seeking packaging solutions that are either biodegradable, recyclable, or utilize recycled content, minimizing environmental footprint. This has a far-reaching impact on machinery manufacturers. The equipment itself must be engineered to handle new, often more challenging, film and adhesive materials—including thinner, bio-based films or specialized recyclable plastic alternatives—without compromising bonding strength or operational speed. Recognizing this industry pivot, leading manufacturers aim to develop technology that supports the use of these eco-friendly materials. The industry's goal is to ensure that post-press finishing processes, including lamination and coating, actively contribute to the overall objective of achieving biodegradable, recycled, and green environmental protection in paper packaging products.

Sunkia Machinery's Core Advantage in Window Laminating Technology

With a focused history spanning over 15 years, Sunkia Machinery has dedicated its resources to the development and manufacturing of high-end post-press machines. This specialization is the foundation of their ability to provide advanced window laminating solutions that directly address the industry's dual pressures of performance and sustainability.

Commitment to Innovative and High Value-Added Machines

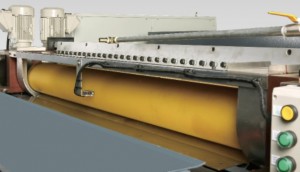

The company's operational philosophy centers on providing innovative packaging surface decoration machines and high value-added machines. This focus goes beyond simply manufacturing equipment; it involves engineering solutions that create superior output quality and operational efficiency for the customer. For window laminating, this translates into machines that manage the entire process—from film feeding and cutting to precise adhesive application and final bonding—with unmatched stability.

The core advantage lies in the integration of surface finishing capabilities. The product lines, including specialized varnishing machine series and various laminating machine models, provide a comprehensive suite of finishing options. This allows the company to develop window laminating solutions that integrate smoothly into complex production lines, whether the box requires a simple protective coating, specialized surface decoration, or structural film integration. This continuity of innovation is driven by a mission to achieve customer success through continuous technological advancement.

Operational Focus and Application Scenarios

Window laminating machines are indispensable across several major packaging segments:

Consumer Electronics Packaging: Used for high-end boxes where product visibility is key, requiring films with optimal clarity and anti-scratch properties. The bonding process must be extremely clean to avoid visual imperfections.

Food and Confectionery: Essential for ensuring hygienic protection and shelf-life extension while allowing consumers to view the product inside. This often involves specific film requirements and adhesive types for food contact safety.

Toy and Retail Packaging: Utilized for durable display boxes that must withstand significant handling and transport while maintaining aesthetic appeal.

In these demanding scenarios, the machinery’s ability to handle a variety of substrate thicknesses and film materials—from thin polyester (PET) to recyclable alternatives—is paramount. The precision and consistent bonding provided by high-end window laminating solutions ensure the finished package not only looks premium but also maintains its structural integrity throughout the supply chain. This technological expertise is critical for any packaging converter aiming to enhance their market position and meet the stringent demands of international brands.

A Vision for Sustainable Post-Press Finishing

The future of post-press finishing is inherently linked to environmental sustainability. Sunkia Machinery’s stated goal is not just about manufacturing speed; it is about utilizing their technique to achieve the goal of biodegradable, recycled, and Green environmental protection in paper packaging products. This focus suggests an ongoing commitment to research and development aimed at improving machine compatibility with eco-friendly consumables.

The packaging and printing industries are currently navigating the complex transition from traditional, often non-recyclable plastic films to innovative sustainable alternatives. A manufacturer that actively positions its technology to facilitate this transition offers significant long-term strategic value to its customers. By continually innovating to manage the unique handling and bonding characteristics of these emerging materials, the company helps packaging producers align their operations with global ecological standards. This commitment to self-achievement through innovation and customer achievement underscores a strategic perspective on the packaging industry's evolving needs, solidifying the company's role as a leading solutions provider in the global marketplace.

Ultimately, the choice of a window laminating solution determines not only the visual appeal and protective qualities of the packaging but also its compliance with future environmental legislation. Selecting a partner with a proven history of specialized innovation and a clear mission focused on high value-added, sustainable machinery provides a resilient pathway for packaging companies to meet the complexities of the modern global market.

For further details on advanced post-press finishing and window laminating solutions, please visit: https://www.sunkiamachinery.com.

Media Contact

Guangdong Sunkia Machinery Technology Co., Ltd. nancy@sunkiamachinery.com +86 0769 82782808 745# Shida Road, Dalingshan Town, Donguan Cicty, Guangdong Province, China https://www.sunkiamachinery.com