Chennai, Tamil Nadu Mar 22, 2022 (Issuewire.com) - WHAT EXACTLY IS A DOCK RAMP?

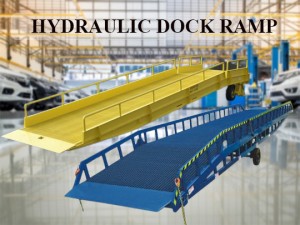

Proper loading dock equipment is critical for ensuring safety and efficiency for businesses in the logistics industry — as well as businesses tangential to the logistics industry. A dock ramp is a piece of logistics handling equipment that works in tandem with a forklift. It is widely used in locations where there is no fixed loading and unloading platform and fluid handling work is common. It has the ability to adjust the height of the yard ramp based on the height of the car compartment. It is appropriate for most vehicles. For batch operations, the forklift can be driven directly into the interior of the car using this device.

Dock ramps are structures that are either permanent or semi-permanent in nature and are used for dock-to-ground loading and unloading. Dock ramps can be moved, but it's not an easy process because they're usually anchored to the ground for security. They're long-lasting, dependable, and designed to provide a permanent loading point at a company's dock doors.

The right dock equipment depends on the needs of the individual business, and comparing the features and capabilities of various options can be challenging at first. This is especially true when it comes to loading ramps. When vehicles regularly dock at the same location, permanent dock ramps help with loading and unloading. Mobile loading docks and yard ramps perform similar functions, but they can be moved around a warehouse or worksite.

HOW WIDE IS A DOCK RAMP?

Dock ramps are available in two designs: rectangle tubular or open truss frames. Sections are available in widths of 4, 5, or 6 feet and lengths of 4, 8, or 12 feet. Any vehicle should be able to dock in a dock area that is adaptable. The most common dock height ranges from 48" to 52". Accessories such as hinges to connect sections and rails to keep the crossing on the dock ramps safe are available.

The parking lot will then slope down to the dock. This slope should ideally be no more than 6%. If heavy loads are to be handled, the slope should be no greater than 3-5 percent. If the space is restricted, you can build the incline to a limit of 10%, which will just work for light loads

WHAT IS THE SIGNIFICANCE OF A DOCK RAMP?

Dock ramps are heavy-duty equipment that is primarily used in special goods handling work in warehouses, wharves, factories, granaries, or logistics centers where a large number of goods must be loaded or offloaded. They are known for their high performance, high quality, sturdy construction, excellent design, ease of maintenance, and ease of use. They are custom-made by specialists to meet all needs and specifications. Furthermore, the ramps provide a stable and dependable performance. They can be used in logistics, packaging and assembly operations, industrial workshops, and other settings.

DOCK RAMPS: DO YOU NEED AN ACCESS RAMP OR A YARD RAMP?

Access ramps (stationary) and yard ramps are the two most common types of ramps (mobile). Which ramp is best for you is determined by your loading/docking area and how you intend to use the ramp.

Yard Ramps are more common because they are more convenient. A yard ramp has heavy-duty wheels that make it simple to move from one location to another with a forklift. Yard ramps are the preferred choice for a quick loading dock solution, especially if you need a ramp in multiple locations all the time.

Because they are bolted to the ground during installation, access ramps are a stationary solution. If the location of your ramp does not need to change, access ramps are the best option for a ground-to-dock solution.

WHAT ARE THE ESSENTIAL CHARACTERISTICS OF A DOCK RAMP?

Length of the ramp - Another critical factor to consider is the length of the ramp in order to achieve the proper freedom and slant to receive loads from the start. You must analyze the area and estimate the exact length of the ramp that you require. Then you should give your information to a forklift ramp manufacturer who can provide you with proficient and adaptable assistance.

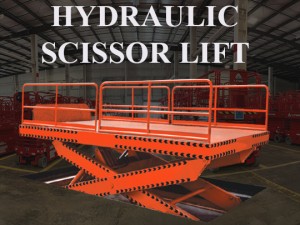

Hydraulic adjustment system - Many ramps come with hydraulic adjustment systems, so keep this in mind when shopping for a forklift ramp. This is due to the hydraulic component providing you with an additional benefit of being able to change the ramp to suit your loading and unloading space well. As a result, your work will be completed more securely, and the safety of your employees will be ensured.

Correct capacity - The simplest and least complicated rule is to multiply the capacity of your heaviest forklift by three. The capacity of the holder ramp you choose should equal or exceed that figure. For example, if your heaviest forklift has a capacity of 2000kg, your ramp capacity should be 6000kg or higher to ensure security and longer working life.

Durability and safety - Toughness is another important aspect of a properly working and long-lasting Dock Ramp edge. The majority of dock levelers have some mileage at the turn focuses. The first priority is safety. They are outfitted with a Safety support swagger to retrieve the unit while performing routine maintenance. When it comes to supporting, our levelers make it simple to grease the pivots because they come with oil fittings.

WHAT IS A WAREHOUSE DOCK RAMP?

Warehouse dock ramps are ideal for materials handling errands because they make moving cargo from ground level to dock height much more productive. Dock-to-ground ramps are commonly used for long-distance loading tasks. The ramps are also intended to make it easier for forklifts to move materials from the dock's initial stage.

For loading and unloading cargo, a warehouse dock ramp and a forklift truck are used. It can be accessed via a press button or a pre-programmed return. This set of collapsing loading ramps shows weight limits ranging from 6000kg to 15000kg. Adopting an anti-slip checked steel plate to ensure the stage's execution is free of slips.

Media Contact

Ferron Equipments *****@gmail.com https://hydraulicdocklevelerrampmanufacturers.blogspot.com/