Dongguan, Guangdong Feb 3, 2026 (Issuewire.com) - Placon roller tracks, often referred to as flow rails or sliding tracks, are specialized conveyor systems designed to facilitate the gravity-fed movement of goods. By utilizing high-quality rollers mounted within durable frames, these tracks enable seamless first-in, first-out (FIFO) inventory management, significantly reducing manual labor and energy consumption in assembly lines and distribution centers. As the global logistics and warehousing landscape undergoes a rapid digital and structural transformation, the demand for efficient material handling solutions has reached unprecedented levels. At the heart of this evolution is the Top China Manufacturer of Placon Roller Tracks, WJ-LEAN Technology Company Limited, which provides essential components that define modern lean production environments.

LogiMAT Insights: Shaping the Future of Material Handling

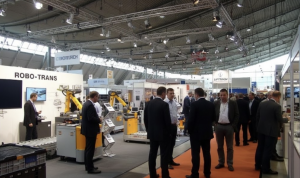

The recent LogiMAT exhibition in Stuttgart served as a pivotal stage for observing the next generation of intralogistics. As one of the world’s most influential trade fairs for distribution, material, and information flow, LogiMAT provided a clear window into the future trends of the industry. The overarching theme observed throughout the event was the integration of high-durability hardware with modular flexibility. This shift reflects a growing necessity for systems that can adapt to the volatile demands of modern e-commerce and high-tech manufacturing.

One German logistics consultant, after testing the load-bearing capacity of the WJ-LEAN Placon systems on-site, remarked on the remarkable smoothness of the flow even under maximum weight capacity. This feedback highlights a critical market shift: clients are no longer just looking for basic components; they are seeking reliability that can withstand the rigors of 24/7 automated environments. The ability to maintain low-friction movement over thousands of cycles is now a baseline requirement for Tier-1 automotive and electronic suppliers.

The trends observed at LogiMAT suggest that the future of Placon roller tracks lies in "Intelligent Modularity." This involves systems that can be reconfigured within minutes to accommodate changing production volumes or product dimensions. WJ-LEAN has aligned its development roadmap with these observations, focusing on lightweight yet high-strength galvanized and aluminum materials. The market's positive reception at the fair validates the company’s direction—moving toward systems that are not only robust but also environmentally sustainable through long-term reusability and complete recyclability of the metal frameworks.

Furthermore, the integration of Placon tracks with automated guided vehicles (AGVs) was a prominent topic of discussion. Future developments will likely see roller tracks equipped with sensor-ready joints that allow for real-time monitoring of inventory levels on the racks. By participating in such high-level forums, WJ-LEAN ensures that its product evolution is dictated by the actual challenges faced by global warehouse managers, securing its position as a forward-thinking leader in the industry.

Engineering Excellence and Technical Innovation

The core competitiveness of WJ-LEAN Technology Company Limited stems from its meticulous approach to industrial construction and technical solution design. Headquartered in Dongguan, Guangdong, the company has established a comprehensive global service layout that bridges the gap between high-end manufacturing and practical on-site application. The technical superiority of their Placon roller tracks is particularly evident in the high-quality galvanized aluminum joints designed for the 35/40/60-series product lines. These components are the result of years of iterative testing to ensure perfect fitment and structural stability.

Unlike standard market offerings, these roller tracks are engineered to minimize friction coefficients. This ensures that goods move consistently without the risk of jamming, which is vital for maintaining the cadence of a high-speed assembly line. This precision is achieved through advanced injection molding techniques for the rollers—using high-grade plastics that resist wear and chemical exposure—and rigorous quality control for the galvanized steel or aluminum housings. The application of these products spans a vast array of sectors, including electronics, auto parts assembly, home appliances, chemicals, and medical equipment.

Innovation at WJ-LEAN is not limited to the product itself but extends to how these products integrate into complex "non-standard" mechanical and electrical systems. The company’s solutions are widely used in mechanical frame structures, industrial inspection equipment, and safety protection systems. By focusing on the "Lean" philosophy, the company ensures that every roller track and joint contributes to the elimination of waste in the production process. This technical depth allows WJ-LEAN to act as a consultant to its clients, providing custom layouts that optimize spatial footprints and worker ergonomics.

The company’s commitment to quality is further evidenced by its adherence to international manufacturing standards. Every piece of equipment, from the smallest joint to the longest conveyor rail, undergoes stress testing to simulate years of industrial use. This dedication to durability is why WJ-LEAN has become a trusted name for global enterprises looking to upgrade their facilities. Their technical solutions do not just solve a current logistical problem; they provide a foundation for scalable growth.

Global Market Expansion and Industry Outlook

The global logistics market is projected to continue its upward trajectory, driven by the expansion of global trade and the increasing automation of manufacturing processes. In this context, participating in premier international exhibitions like LogiMAT is a strategic step in WJ-LEAN’s globalization strategy. It allows the company to synchronize its research and development with international standards and to establish localized service agencies that can provide immediate support to a diverse, multi-national clientele.

As WJ-LEAN continues to expand its footprint in the global market, its focus remains on the synergy between technical innovation and market needs. The transition from being a regional leader to a global benchmark involves a constant feedback loop with international partners. By staying at the forefront of the trends observed at global forums, the company ensures that its Placon roller tracks are not just components of the present but foundational elements of the future’s smart factories.

Looking ahead, the role of material handling will only become more integrated. We are moving toward an era where the physical track and the digital data stream merge. WJ-LEAN is already preparing for this by refining the tolerances of its tracks to support more sensitive automated picking systems. The goal is to provide a seamless infrastructure that supports the "lights-out" factory of tomorrow while maintaining the cost-effectiveness and simplicity that lean manufacturing demands. Through a combination of global vision and local manufacturing excellence, the company is well-positioned to lead this transition.

For more information on high-performance lean solutions, product applications, and technical specifications, please visit the official website: https://www.wj-lean.com/

Media Contact

WJ-LEAN TECHNOLOGY (DONGGUAN) COMPANY LIMITED info@wj-lean.com