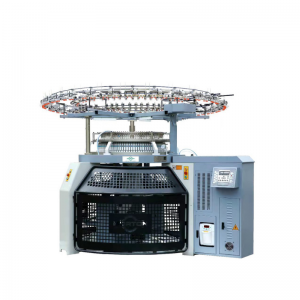

Quanzhou, Fujian Dec 8, 2025 (Issuewire.com) - The global textile industry is currently navigating a pivotal phase, marked by increasing demand for high-quality, sustainable, and highly customizable knitted fabrics. The engine driving this transformation is the Circular Knitting Machine, a critical piece of equipment renowned for its efficiency and versatility in producing seamless tubular fabric. In this dynamic landscape, manufacturers from China have emerged as significant global players. When evaluating the Top 10 Suppliers Of Circular Knitting Machine In China, one name that consistently stands out for its commitment to precision engineering and global service standards is Quanzhou Morton Machinery Co., Ltd., better known as Morton Machine.

Morton Machine has strategically positioned itself not just as a high-volume producer, but as a specialist focused on engineering excellence. Their dedication to producing state-of-the-art knitting technology is a key factor in the company’s international reputation.

The Evolving Landscape of Circular Knitting

The industry background underscores a clear trend: the market for circular knitting technology is robust and projected to grow. Factors driving this expansion include the rising global demand for comfortable knitwear, the explosive growth in athleisure and technical textiles, and the move towards more sustainable manufacturing processes.

Seamless and Efficiency Focus: Modern textile production heavily favors seamless garment manufacturing and high-speed efficiency. Circular knitting machines provide continuous, high-speed output and inherently reduce material waste by eliminating extensive cut-and-sew operations.

Versatility in Fabric: The machines must be capable of handling a diverse range of fibers and producing complex structures like jacquard, fleece, rib, and interlock for applications spanning fashion, medical textiles (like tubular bandages), and automotive interiors.

This context of increasing technological sophistication and global market demand sets the stage for manufacturers who can deliver on quality and reliability.

The Morton Machine Core Advantage: Precision and Stability

Morton Machine has built its reputation by prioritizing machine stability and knitting precision. Their core product line is comprehensive, including Single Jersey, Double Knit, Rib, Fleece, Terry, Interlock, and Seamless machines, often categorized into "European Classic Version" and "European Version" to denote their high-end, precision-focused design.

The key to their competitive edge lies in several engineering features that contribute directly to higher production quality and operational longevity:

Superior Engineering and Material Science

Morton Machine emphasizes the use of high-end materials and imported CNC machining for critical components. A notable core advantage is their specialized structural design—Morton is one of the few Chinese manufacturers utilizing a unique design, such as the suspended wire bearing with an aluminum cam box. This design is crucial for enhancing machine stability and vibration reduction, especially when running at high speeds. Stable operation is directly linked to producing fabrics with fewer defects, better stitch uniformity, and greater consistency—essential for meeting the stringent quality requirements of international textile brands.

Product Application and Versatility

The breadth of the Morton product catalog demonstrates their commitment to versatility. Their specialized machines cater to diverse end-products, showcasing their capability to meet specific market needs:

Seamless Knitting Machines: These are critical for the booming activewear and intimate apparel markets, allowing for the creation of tubular garments with minimal waste.

High-Speed Interlock Knitting Machines: Used to produce dense, stable fabrics suitable for sophisticated apparel and technical applications. The complexity and precision of these machines are often cited in client success stories, such as the development of precision interlock fabric for car interior innovators—a key application of technical textiles.

Terry and Fleece Machines: These enable the production of cozy fabrics for casual wear and blankets, illustrating the machine's ability to handle different loop structures and yarn types (surface yarn, bottom yarn, loop yarn).

This diverse application capability highlights Morton's role in facilitating a wide array of textile production across the globe.

A Focus on Global Service and Customer Support

While advanced technology is the foundation, Morton Machine’s global appeal is reinforced by its full-spectrum service model. Recognizing that a complex piece of capital equipment requires continuous support, the company provides integrated services that extend far beyond the initial sale:

End-to-End Partnership: Morton’s service spans pre-sale consulting and design to comprehensive after-sale support. This includes technical assistance with raw material selection, on-site training, computer system support, and machine adjustment.

Timely and Conscientious Support: The company’s philosophy centers on minimizing customer downtime and maintenance costs. The commitment to rapidly addressing any potential operational issue is what builds sustained trust with its global clientele, who often operate on tight production schedules.

This focus on partnership, technical support, and the quick resolution of issues distinguishes Morton Machine in a highly competitive manufacturing sector, proving that service quality is just as vital as machine quality in setting the Global Standard for the industry.

Conclusion

In an industry where the demand for high-quality, specialized knitwear is only accelerating, the role of a reliable and technologically advanced machine supplier is paramount. Quanzhou Morton Machinery Co., Ltd. has established itself as a frontrunner among Chinese manufacturers of the Circular Knitting Machine.

By adhering to a standard of precision engineering, evident in features like the suspended wire bearing design, and coupling this with a robust global support system, Morton Machine is not just keeping pace with industry trends—it is actively helping to define them. For textile producers seeking a reliable partner for their next generation of high-speed, high-quality, and versatile knitting solutions, Morton Machine’s track record of stability and technical excellence provides a compelling case.

For more information on their product range and engineering philosophy, visit their official website: https://www.mortonknitmachine.com/.

Media Contact

Quanzhou Morton Machinery Co., Ltd. joanna@mortonknitmachine.com 0086-13004894622 No.168, Dunding, Jiaonan, Heshi Town, Luojiang District, Quanzhou City, Fujian Province,China. https://www.mortonknitmachine.com/