Wuxi, Jiangsu Jan 16, 2026 (Issuewire.com) - As global high-temperature industries continue to push the limits of efficiency, durability, and sustainability, advanced ceramic materials are becoming essential to modern kiln systems. In this context, High-quality SiSiC/RBSIC/silcon carbide beam products have emerged as a critical solution for extreme heat zones, offering exceptional load-bearing capacity, thermal stability, and long service life. HUANSHANG HIGHTECH CO., LTD, also known as HUAN SHANG (YIXING) INC, stands at the forefront of this technological evolution, delivering reliable SiSiC and RBSIC carbide beams designed for demanding industrial kiln environments.

Silicon carbide (SiC) kiln furniture, particularly reaction bonded silicon carbide (RBSIC/SiSiC) beams, has become a cornerstone in modern high-temperature processing. Compared with traditional refractory materials, SiSiC beams offer significantly higher mechanical strength at elevated temperatures, excellent thermal shock resistance, low deformation under long-term load, and superior corrosion resistance. These characteristics make them ideal for kiln support structures operating in continuous high-load and high-temperature conditions, such as roller kilns, tunnel kilns, and shuttle kilns.

Industry Outlook: Growth Driven by High-Temperature Manufacturing and Energy Transition

The global market for advanced kiln furniture and heat-resistant materials is experiencing steady growth, driven by structural changes across multiple industries. Ceramics, bricks and tiles, lithium battery materials, solar energy components, powder metallurgy, and precision casting are all undergoing rapid expansion. These sectors demand higher firing temperatures, stricter dimensional tolerances, and longer production cycles, placing unprecedented requirements on kiln systems and their internal support components.

In the ceramic and brick industries, manufacturers are transitioning toward larger-format products, thinner slabs, and faster firing cycles. This shift increases the mechanical and thermal stress on kiln furniture, accelerating the replacement of conventional alumina and cordierite materials with high-performance silicon carbide solutions. SiSiC/RBSIC beams, with their high modulus of elasticity and low creep rate, are increasingly specified as standard components in new kiln designs.

At the same time, the global energy transition is reshaping industrial material demand. Lithium battery cathode and anode materials, photovoltaic components, and advanced magnetic materials all require precise thermal processing under controlled atmospheres. These applications often involve aggressive chemical environments and repeated thermal cycling, conditions under which traditional refractory supports struggle to maintain performance. Silicon carbide kiln furniture, known for its chemical inertness and oxidation resistance, aligns perfectly with these emerging needs.

Environmental regulations and cost pressures are also influencing market trends. Longer service life and reduced kiln downtime directly translate into lower operational costs and reduced waste. As manufacturers aim to improve energy efficiency and reduce carbon footprints, lightweight yet high-strength kiln furniture such as SiSiC beams contributes to lower thermal mass, faster heating and cooling, and improved overall kiln efficiency.

Looking ahead, the industry is expected to continue moving toward customized, application-specific kiln furniture solutions. Digital kiln design, automated handling systems, and higher levels of process integration will further increase demand for dimensionally precise, mechanically reliable silicon carbide components. Companies with comprehensive product portfolios, strong R&D capabilities, and stable production capacity will be best positioned to benefit from these long-term trends.

HUANSHANG HIGHTECH: Core Strengths and Comprehensive Solutions

Founded in 2005, HUANSHANG HIGHTECH CO., LTD is a foreign-invested enterprise with nearly two decades of experience in high-temperature materials. Operating under the names HUANSHANG HIGHTECH CO., LTD and HUAN SHANG (YIXING) INC, the company has developed into a group enterprise with three family-owned factories, each specializing in different product categories. This integrated structure enables HUANSHANG to maintain strict quality control while offering a broad and flexible product range.

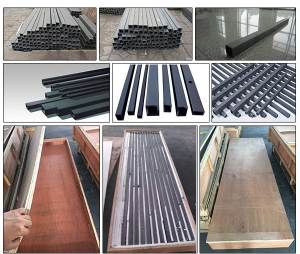

One of HUANSHANG’s core manufacturing facilities is dedicated to sintered silicon carbide products, with a strong focus on reaction bonded silicon carbide (RBSIC/SiSiC) and oxide silicon carbide kiln furniture. The company is now recognized as one of the industry players with the most complete range of kiln furniture types and specifications, covering beams, battens, plates, rollers, setters, and customized structural components.

HUANSHANG SiSiC/RBSIC carbide beams are engineered for high-load kiln support in extreme heat zones. Their key advantages include high bending strength even above 1300°C, minimal thermal expansion, excellent resistance to oxidation and corrosion, and outstanding dimensional stability over long service cycles. These properties make them especially suitable for large-span kiln structures and heavy product loads, where safety and reliability are critical.

The company’s products are widely used across diverse industries, including ceramic tiles and sanitary ware, bricks and refractories, microcrystalline stone, foam ceramic insulation materials, powder metallurgy, lithium battery materials, solar energy components, magnetic materials, abrasive tools, geological prospecting and analysis, precision casting, food processing, and the steel industry. This broad application spectrum reflects HUANSHANG’s ability to adapt material solutions to different thermal, mechanical, and chemical requirements.

HUANSHANG’s customer base includes kiln manufacturers, large-scale ceramic producers, and advanced material companies both in China and international markets. Through long-term cooperation, the company has accumulated extensive application data and practical experience, enabling it to provide not only products but also technical support and optimization suggestions for kiln design and operation. Many customers report extended service life, reduced maintenance frequency, and improved firing consistency after adopting HUANSHANG SiSiC/RBSIC beams.

In addition to its core kiln furniture business, HUANSHANG HIGHTECH has strategically invested in and acquired other factories, strengthening its position as a comprehensive group company in heat-resistant materials. This diversified structure enhances supply chain stability, supports continuous innovation, and allows the company to respond quickly to changing market demands.

Commitment to Quality and Long-Term Partnership

Quality, reliability, and customer trust are central to HUANSHANG’s corporate philosophy. From raw material selection to forming, sintering, and final inspection, every production stage is managed under strict internal standards. The company continuously invests in equipment upgrades and process optimization to ensure consistent product performance across batches.

As high-temperature industries evolve toward higher efficiency and sustainability, HUANSHANG HIGHTECH remains committed to delivering advanced silicon carbide solutions that support its customers’ long-term success. By combining industry insight, manufacturing expertise, and a comprehensive product portfolio, the company aims to be a reliable partner in the global kiln furniture and heat-resistant materials market.

For more information about HUANSHANG SiSiC/RBSIC carbide beams and other high-temperature solutions, please visit https://www.hshightec.com/.

Media Contact

HUANSHANG HIGHTECH CO., LTD hshightech@outlook.com https://www.hshightec.com