Xiamen, Fujian Feb 10, 2026 (Issuewire.com) - As global demand for minerals, metals, and critical raw materials increases, mining operations are expanding further than ever before in size and complexity. They now span across an increasing spectrum of locations from Quanzhou in China all the way through to Australia. Open-pit mines, underground operations, and large quarry sites push heavy equipment to its limit; components must withstand extreme impact, abrasion, and continuous operation for successful operation. Bucket teeth have quickly become one of the most critical wear parts influencing productivity, machine efficiency, and total operating costs in today's high-pressure environment. Established in 1998, Xiamen Globe Machine Co., Ltd. (GT) has garnered an impeccable international reputation as an authority on construction and mining spare parts. Today, GT stands out for offering Global Leading High Quality Forged Bucket Teeth from their modern production facility in Quanzhou, trusted by equipment operators worldwide.

Mining Industry Requirements: Why Bucket Teeth Quality Is Essential

Excavators and mining shovels play a pivotal role in modern mining operations, transporting thousands of tons of material every day. Their performance directly affects digging efficiency, fuel consumption, machine stability, maintenance frequency, and replacement frequency, with low-quality bucket teeth often breaking, chipping, or wearing out rapidly, forcing costly replacements as well as machine downtime.

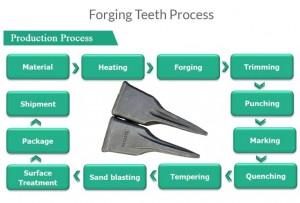

Mining companies are increasingly looking toward premium forged bucket teeth as an affordable and superior way to improve strength, consistency, and durability. Forged bucket teeth are made by high-pressure shaping of heated steel under high-pressure shaping to improve impact resistance and wear performance - proven more reliable in harsh environments such as iron ore mining sites than casting methods, such as copper mining sites, gold mines, or coal mines.

GT has closely observed this industry trend and invested significantly in forging technology, material engineering, and advanced heat treatment processes to ensure its bucket teeth meet global performance standards.

Comparison of Forged vs Cast Bucket Teeth Performance Analysis

To gain an appreciation of why GT's forged bucket teeth stand out, it is necessary to compare them against conventional cast alternatives on various key performance indicators:

Cast bucket teeth tend to crack under heavy impact loads, particularly when encountering hard rock or uneven terrain. By contrast, forged bucket teeth exhibit greater toughness due to their refined grain structure, enabling them to absorb shock without cracking or breaking.

Field tests conducted by GT's partners on large mining projects have demonstrated that using forged teeth reduces unexpected breakage rates by 40-60%, greatly improving operational reliability.

Wear Longevity

Mining environments can be highly abrasive environments that lead to rapid material loss from standard cast teeth. GT's forged bucket teeth undergo special heat treatments designed to increase surface hardness while simultaneously maintaining core toughness for longer wear life and more predictable replacement cycles.

Many GT customers report that forged teeth last 1.5 to 2 times longer than conventional cast options, cutting costs associated with spare parts consumption and maintenance work.

Consistency and Quality Control.

Casting processes may introduce internal defects such as air bubbles and weak spots that compromise structural integrity. GT's forging process produces more uniform and defect-free components. We further reinforce this advantage through rigorous metallurgical testing and quality documentation processes.

Each production batch comes complete with:

Heat Treatment Reports, Hardness Test Reports, and Material Certificatesalitat These documents offer complete transparency on mechanical properties, alloy composition, and durability benchmarks for every purchase, giving customers confidence when making decisions based on mechanical property analysis.

Cost Efficiency Over Time (CIOT)

Though forged bucket teeth may cost slightly more upfront, their longer service life and decreased failure rate result in lower total cost of ownership for mining companies. By eliminating replacements, reducing downtime, and improving machine productivity, mining firms save money through reduced replacement expenses, reduced replacement time, and productivity increases.

Since 1998, Xiamen Globe Machine has been known for engineering excellence.

Established nearly 30 years ago, Xiamen Globe Machine Co. Ltd has quickly grown from a regional manufacturer into an internationally-recognized provider of heavy machinery spare parts. Operating out of its cutting-edge facility in Quanzhou, this company produces high-performance components for:

Bulldozers, Excavators, Cranes, and Drilling Rigs.

Mining trucks

Although GT's core expertise lies in premium undercarriage components--such as track rollers, idlers, sprockets, and track links--they have broadened their product offering to include hydraulic breakers, buckets, pins, bushings, and engine components.

GT's comprehensive catalog serves as a one-stop solution for construction and mining companies, streamlining procurement while guaranteeing compatibility across various equipment brands such as Caterpillar, Komatsu, Volvo, Hitachi, Hyundai, and Doosan.

Buck Teeth is widely known for its superior manufacturing capabilities, and its manufacturing capacities are now capable of creating these superior teeth products.

GT's success in forging bucket teeth rests upon advanced technology, expert engineering design, and stringent quality management practices.

Advanced Forging and Heat Treatment Solutions

Our company utilizes high-capacity forging presses and precision heat treatment systems to enhance mechanical properties such as hardness, tensile strength, and fatigue resistance - essential attributes for heavy mining applications.

Precision Machining & Inspection :

Once forging is complete, every bucket tooth goes through CNC machining and automated inspection to ensure dimensional accuracy and perfect compatibility with standard adapters and shanks.

GT sources premium alloy steels designed specifically to handle extreme environments, with every batch fully traceable through Material Certificates that guarantee compliance with international metallurgical standards.

Certifications That Strengthen Global Trust

GT's global reputation rests upon quality assurance: GT holds internationally-recognized certifications that validate product performance and responsible manufacturing practices;

- ISO 9001:2015 -- Quality Management System

ensures standardized production processes, consistent product quality, and continuous improvement.

- ISO 14001:2015 -- Environmental Management System

Demonstrates commitment to sustainable operations, waste reduction, and energy efficiency.

- CE Certification

Certifying compliance with stringent European safety and performance regulations enables market access across Europe.

GT's certifications, combined with extensive technical documentation, make us the go-to supplier for major distributors and mining contractors worldwide.

Real World Mining Applications

GT Forged Bucket Teeth are widely utilized across various applications:

Australia and Brazil both conduct iron ore mining activities.

Copper mining activities take place in Chile and Peru.

West African Gold Mining Activities

Coal mining operations in Indonesia and South Africa

GT's teeth consistently deliver reliable performance in each environment, helping operators maximize uptime while reducing maintenance costs.

Long-Term Partnerships and Global Reach

GT has 28 years of international experience and has successfully created a robust distribution network spanning Europe, North America, South America, the Middle East, and Southeast Asia. GT places special importance on long-term collaboration by offering:

Technical Advice, Custom Designed Products, and Reliable After-Sales Support are some of the services that may be provided during a consultation process or order process.

Many global dealers rely on GT as not just a supplier but as an active partner in manufacturing operations.

Innovation and the Future of Mining Wear Parts

As part of its investment plans for the future, Xiamen Globe Machine is investing in digital manufacturing, automated quality inspection, and material research to enhance product performance and create more innovative wear parts designed specifically for autonomous and hybrid mining machinery. Furthermore, the company is seeking partnerships with major equipment manufacturers in order to produce them more cost-effectively.

As mining operations become more technologically advanced, GT continues to push the envelope on durability, efficiency, and sustainability in forged bucket tooth design.

Conclusion: Enhancing Performance and Longevity

GT's transformation from local manufacturer to globally trusted brand demonstrates its unyielding focus on quality, innovation, and customer value. Through innovative forging techniques, stringent quality control measures and years of industry expertise, Xiamen Globe Machine has earned its status as a global provider of High Quality Forged Bucket Teeth that set new standards in performance and longevity for mining operations worldwide.

GT offers mining companies looking for high-performance wear parts with long service lives at cost-effective prices, reliable wear parts with real, measurable operational advantages.

For more information, visit: bestpartscn.com

Media Contact

Xiamen Globe Machine Co., Ltd. sunny@xmgt.net +0086-13860439542