Wuxi, Jiangsu Jan 16, 2026 (Issuewire.com) - As semiconductor manufacturing and advanced high-temperature processing continue to evolve toward higher precision, automation, and productivity, the role of critical structural components inside furnaces is becoming increasingly important. In the center of this technological transition, Future Leading SiSiC/RBSIC/silcon carbide Cantilever Paddle products are emerging as a key solution for stable wafer handling and continuous kiln operation under extreme thermal conditions. HUANSHANG HIGHTECH CO., LTD, also known as HUAN SHANG (YIXING) INC, leverages its long-standing expertise in silicon carbide materials to deliver advanced cantilever paddles that combine lightweight design, exceptional strength, and long-term dimensional stability.

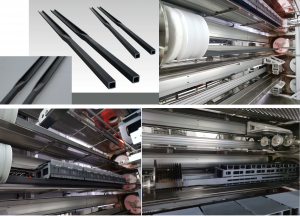

Silicon carbide cantilever paddles are core components of semiconductor wafer loading systems. Manufactured from reaction bonded silicon carbide (SiSiC/RBSIC), these paddles maintain excellent mechanical stability without deformation at high temperatures, even during long-term continuous operation. Their high wafer loading capacity makes them particularly suitable for robotic automatic loading and handling systems. Because the cross-section of the cantilever paddle remains stable and does not deform, existing furnace tubes can be used to process larger-diameter wafers, enabling higher production efficiency without major equipment replacement. In addition, the thermal expansion coefficient of SiSiC cantilever paddles closely matches that of LPCVD coatings, making them ideal for LPCVD processes by significantly extending maintenance and cleaning cycles while greatly reducing contamination.

Industry Outlook: Semiconductor Expansion and Advanced Kiln Technologies

The global semiconductor industry is entering a new growth cycle driven by artificial intelligence, electric vehicles, renewable energy, and advanced consumer electronics. As chip architectures become more complex and wafer sizes increase, thermal processing steps such as LPCVD, diffusion, and oxidation demand ever-higher levels of stability and cleanliness. This trend is directly accelerating demand for advanced furnace components made from high-purity, high-performance materials like silicon carbide.

One of the most notable trends is the shift toward larger wafer diameters and higher throughput. Manufacturers are under constant pressure to maximize output per furnace cycle while maintaining strict uniformity and yield. Cantilever paddles must support heavier wafer loads while preserving precise positioning throughout repeated high-temperature cycles. Traditional quartz or metallic components face limitations in strength, deformation resistance, and service life, opening the door for SiSiC/RBSIC solutions.

Automation is another powerful driver. Modern semiconductor fabs increasingly rely on robotic handling systems to reduce human intervention and contamination risk. Cantilever paddles must be compatible with automated loading and unloading, requiring consistent geometry, high stiffness, and predictable thermal behavior. Silicon carbide’s combination of low thermal expansion and high modulus makes it especially suitable for these automated environments.

Beyond semiconductors, continuous kilns used in advanced ceramics, powder metallurgy, magnetic materials, and lithium battery materials are also evolving toward longer operating cycles and higher temperature stability. Lightweight yet strong structural components help reduce mechanical stress on kiln systems and improve energy efficiency. As a result, advanced SiSiC components are increasingly specified not only for wafer processing but also for broader high-temperature industrial applications.

Environmental and cost considerations further reinforce these trends. Longer maintenance intervals, reduced particle generation, and lower replacement frequency directly translate into lower operating costs and higher equipment uptime. As manufacturers focus more on total lifecycle cost rather than initial investment, advanced silicon carbide components gain a clear competitive advantage.

Looking ahead, the market outlook for SiSiC/RBSIC cantilever paddles and related high-performance kiln furniture remains highly positive. Continued investment in semiconductor fabrication, combined with upgrades across high-temperature processing industries, will sustain long-term demand for materials that can deliver precision, durability, and cleanliness under extreme conditions.

HUANSHANG HIGHTECH: Advanced Manufacturing for Critical Furnace Components

Founded in 2005, HUANSHANG HIGHTECH CO., LTD is a foreign-invested enterprise specializing in high-temperature and heat-resistant materials. Operating under the names HUANSHANG HIGHTECH CO., LTD and HUAN SHANG (YIXING) INC, the company manages three family-owned factories, each focused on different product categories. This structure allows HUANSHANG to combine deep specialization with group-level integration and long-term strategic investment.

One of HUANSHANG’s core factories is dedicated to the manufacturing of sintered silicon carbide products, including reaction bonded silicon carbide (RBSIC/SiSiC) and oxide silicon carbide components. While the company is widely recognized for its kiln furniture solutions—such as beams, rollers, radiant tubes, heat exchanger tubes, cold air tubes, and setters—the same material expertise underpins its SiSiC/RBSIC cantilever paddle products.

HUANSHANG’s silicon carbide cantilever paddles are engineered to meet the stringent requirements of semiconductor furnace systems. Their stable cross-sectional geometry ensures minimal deformation at high temperatures, supporting large wafer loads with high positional accuracy. This stability enables customers to process larger wafers using existing furnace tubes, improving capacity utilization and reducing capital expenditure.

In LPCVD applications, HUANSHANG SiSiC cantilever paddles offer a significant advantage due to their thermal expansion compatibility with LPCVD coatings. This compatibility reduces coating stress and flaking, leading to longer maintenance and cleaning cycles and significantly lower contamination levels. Customers benefit from improved yield, reduced downtime, and more consistent process performance.

The company’s products serve a wide range of industries beyond semiconductors, including ceramics, bricks and tiles, microcrystalline stone, foam ceramic insulation materials, powder metallurgy, lithium battery manufacturing, solar energy, magnetic materials, abrasive tools, geological prospecting and analysis, precision casting, food processing, and the steel industry. In continuous kilns and high-temperature furnaces, HUANSHANG’s silicon carbide components contribute to stable operation and extended service life.

Customer projects include semiconductor fabs adopting automated wafer handling systems, where HUANSHANG cantilever paddles support high-throughput, low-contamination processing. In advanced ceramic and powder metallurgy lines, customers report improved kiln stability and reduced maintenance frequency after upgrading to HUANSHANG SiSiC components.

A key competitive advantage of HUANSHANG HIGHTECH is its comprehensive product portfolio. As a group company that has also acquired and invested in additional factories, HUANSHANG is now recognized as one of the industry players with a relatively complete range of kiln furniture and heat-resistant materials in terms of types and specifications. This allows customers to source integrated solutions from a single, reliable supplier.

Precision, Stability, and Long-Term Partnership

Quality control is central to HUANSHANG’s manufacturing philosophy. From raw material selection and forming to sintering, machining, and final inspection, each production step is managed under strict internal standards. Continuous investment in equipment and process optimization ensures consistent performance and dimensional accuracy across batches.

HUANSHANG HIGHTECH positions itself not just as a supplier, but as a long-term partner for customers operating in high-temperature and high-precision environments. By combining material science expertise, application knowledge, and scalable manufacturing capability, the company helps clients achieve higher efficiency, lower contamination risk, and sustainable production growth.

As semiconductor technology and continuous kiln systems continue to advance, SiSiC/RBSIC cantilever paddles will remain a cornerstone component for reliable, high-performance furnace operation. HUANSHANG HIGHTECH CO., LTD is committed to driving this future with advanced silicon carbide solutions built for precision, durability, and innovation.

For more information about HUANSHANG’s SiSiC/RBSIC cantilever paddles and comprehensive high-temperature material solutions, please visit https://www.hshightec.com/.

Media Contact

HUANSHANG HIGHTECH CO., LTD hshightech@outlook.com https://www.hshightec.com