Shenzhen, Guangdong Jan 19, 2026 (Issuewire.com) - In today’s highly competitive electronics manufacturing environment, power stability has become a defining factor in product quality, testing accuracy, and overall production efficiency. As factories adopt automated testing platforms, high-density production lines, and long-duration aging processes, DC power systems are no longer treated as basic utilities, but as critical infrastructure. Within this context, selecting the right power supply partner is a strategic decision rather than a simple procurement choice. As a China Leading DC Power Supplier, Jetronl Instruments Co., Ltd. provides DC power solutions designed to support the real operational demands of modern electronics factories.

This guide explains how electronics manufacturers can evaluate DC power supply partners, what technical and operational factors truly matter, and why working with an experienced supplier like Jetronl can directly improve yield rates, testing consistency, and long-term reliability across production and R&D environments.

The Changing Role of DC Power in Electronics Manufacturing

Electronics factories today operate far beyond traditional assembly-and-test models. Whether producing communication modules, LCD displays, navigation equipment, home appliances, opto-mechatronics production equipment, automotive electronics, or integrated circuit (IC) devices, most facilities now rely on automated workflows where power stability directly affects test repeatability, product performance, and production line efficiency.

In functional testing, DC power supplies must deliver precise voltage and current profiles to simulate real operating conditions. Even minor ripple or transient instability can cause false failures or inconsistent test results. During aging and endurance tests, power systems are expected to operate continuously for hundreds or thousands of hours while supporting large numbers of units simultaneously.

For example, in an LCD module factory, thousands of panels may undergo burn-in testing at the same time. The DC power system must maintain stable output across all channels over extended periods, ensuring that test data remains reliable from start to finish. In automotive electronics production, control modules often require testing under different voltage conditions to replicate vehicle operating scenarios, placing higher demands on power programmability, response time, anti-interference pulse capability, and ripple suppression performance.

As these requirements increase and evolve, factories are shifting from one-off power purchases to long-term partnerships with suppliers capable of providing stable, scalable, and well-supported DC power solutions.

A Practical Framework for Choosing a DC Power Supply Partner

When evaluating DC power suppliers, electronics manufacturers increasingly focus on several key criteria:

- Maintenance of output stability and data precision under both steady and dynamic loads

- Programmable control to support multiple test schemes and automation

- Modular architecture that allows capacity expansion without the need for system redesign

- Reliability and consistency in continuous-operation environments (such as aging tests)

- Technical processes and integration support tailored to real production scenarios

A supplier that can consistently meet these criteria is more likely to support sustained production growth and reduce long-term operational risk.

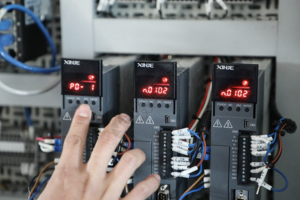

How Jetronl’s DC Power Solutions Address New Factory-Level Challenges

Jetronl’s DC power supplies are developed with industrial application scenarios as the primary design reference. Programmable DC power systems are widely used in various electronics manufacturing plants, such as for functional testing of communications, navigation equipment, automotive electronics, home appliances, opto-mechatronics equipment, automated test systems and production lines, IC device display drivers, and control boards. Engineers can define voltage ramp-up and ramp-down sequences and timing, current limits, and protection thresholds based on product specifications, ensuring that technical process requirements are met and reducing the risk of damage to components and parts during testing.

In a typical communication device manufacturing facility, Jetronl’s modular DC power systems are installed in automated test racks where dozens of units are powered and tested simultaneously. Independent channel control ensures that each device receives a stable power supply without mutual interference, while the modular structure allows for continuous expansion as production volumes grow.

In aging and reliability testing environments, Jetronl’s DC power supplies support long-term, uninterrupted operation under sustained load. For aging or endurance tests of consumer electronics, LCD panels, and more, long-term stable voltage output helps manufacturers identify latent defects before products enter the market. This contributes directly to improved yield, stability, and reduced after-sales failure rates.

Automotive electronics factories benefit most from Jetronl’s DC power solutions. During testing of electronic control units, battery system controls, communication modules, lighting modules, and various sensor systems, programmable power supplies can simulate different vehicle voltage and current conditions. Consistent response behavior under rapid load changes ensures accurate evaluation and supports compliance with strict quality standards.

Supporting High-Density and Automated Test Environments

As electronics production becomes more automated, DC power systems must integrate smoothly into broader testing and control frameworks. Jetronl’s DC power solutions are designed to support centralized control and standardized interfaces, making them suitable for automated test platforms and semi-automated production lines.

For example, in IC testing and calibration environments, multiple devices may require simultaneous power under tightly controlled conditions. Jetronl’s modular DC power architecture allows test engineers to configure multi-output systems within a unified framework, simplifying wiring, monitoring, and maintenance.

This approach reduces system complexity while supporting scalability—an important advantage for factories facing frequent product updates or expanding testing requirements.

The Value of Engineering Support and Long-Term Partnership

While hardware performance is essential, electronics factories also benefit from working with suppliers who understand production realities. Jetronl’s engineering teams provide scenario-based recommendations, helping customers select appropriate power configurations based on load characteristics, test duration, and automation requirements.

In one typical case, a factory producing video processing boards required synchronized multi-voltage testing across numerous channels. By adopting a modular DC power configuration tailored to this workflow, the factory was able to streamline testing procedures and time while maintaining consistent electrical performance across all units.

Research laboratories, universities, and calibration institutions also rely on Jetronl’s DC power systems as flexible platforms for experimentation and verification. The ability to adjust output ranges and expand system capacity over time allows these institutions to adapt to evolving research needs without replacing core infrastructure.

Building a Future-Ready Power Infrastructure

As electronics manufacturing continues to evolve toward higher precision, tighter quality standards, and increased automation, DC power supply systems will remain a foundational element of production success. Partnering with a China Leading DC Power Supplier that prioritizes stability, scalability, and practical integration provides manufacturers with a clear competitive advantage.

Jetronl’s DC power solutions are widely applicable across electronics production, R&D, technical processes, testing, and aging test environments. By aligning power system design with real factory requirements and offering long-term engineering support, Jetronl helps manufacturers build power infrastructure that is reliable today and adaptable for the future.

To learn more about Jetronl’s solutions or explore partnership opportunities, visit the official website: https://www.jetronlinstrument.com/.

Media Contact

Jetronl Instruments Co., Ltd. jetronl@qq.com Room 402, Yanda Technology Park, No. 116, Shuiku Road, Xixiang Street, Baoan District, Shenzhen https://www.jetronlinstrument.com/