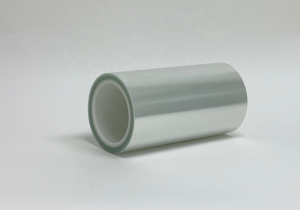

Foshan, Guangdong Jan 18, 2026 (Issuewire.com) - Foshan AoChuanShun New Material Industrial Co., Ltd. (ACS) has initiated a new technical disclosure aimed at defining the performance benchmarks for functional film procurement in the global market. As a specialized High Quality PET Plastic Film Factory, ACS focuses on the production of engineered polyethylene terephthalate (PET) substrates that address the critical gap between standard protection and precision material engineering. These films are produced using biaxially-oriented technology to ensure maximum tensile strength and thermal stability. By implementing a multi-stage coating process, the factory develops specialized surface treatments that offer specific adhesion levels, ranging from ultra-low tack for optical lenses to reinforced wear-resistant layers for automotive components, ensuring that high-value substrates remain pristine throughout manufacturing and international logistics.

Global Manufacturing Shifts: The Rising Standards for Functional Media

The international industrial landscape is witnessing a structural shift in how surface integrity is managed. As high-tech manufacturing moves toward 5G integration, electric mobility, and advanced optoelectronics, the role of the film supplier has evolved from a commodity provider to a strategic technical partner.

1. Automation and Mechanical Stress Management In the era of Industry 4.0, the widespread adoption of high-speed robotic assembly lines has introduced new variables into surface protection. Traditional films often fail under the shear forces and friction generated by robotic grippers. The industry trend is now moving toward PET films with verified mechanical durability. These materials must possess the surface hardness to resist scuffing while maintaining the flexibility to conform to complex 3D geometries, such as curved smartphone displays or contoured automotive dashboards.

2. Optical Purity and Inspection Compatibility The proliferation of OLED and ultra-high-definition (UHD) display technologies has placed unprecedented demands on the optical purity of protective films. Modern factories require materials with ultra-low haze and high light transmittance. This allows for automated optical inspection (AOI) to occur without removing the protective layer, thereby reducing the risk of contamination in the final stages of assembly. Suppliers are increasingly required to provide data on surface inclusions and gel counts to guarantee that the film does not interfere with precision sensor calibration or visual inspection.

3. Thermal Stability and Dimensional Precision As manufacturing processes involve higher processing temperatures—such as in the curing of electronic adhesives or the thermoforming of plastic parts—the thermal stability of the PET substrate has become paramount. Industry-leading films must exhibit low thermal shrinkage to prevent edge curling or adhesive migration. This dimensional stability ensures that the film remains perfectly aligned with the substrate during heat-intensive cycles, preventing production downtime or surface defects.

4. Surface Energy and Adhesion Dynamics Modern substrates, ranging from anti-fingerprint glass to low-energy plastics, present unique challenges for adhesive bonding. The industry is moving toward "tailored adhesion," where the chemical interaction between the adhesive and the substrate is precisely calibrated. This prevents the "adhesion build-up" phenomenon, where the film becomes increasingly difficult to remove over time, potentially damaging the very surface it was meant to protect.

Corporate Excellence: Technical Infrastructure and Strategic Advantages

Foshan AoChuanShun New Material Industrial Co., Ltd. (ACS) addresses these evolving global requirements through a manufacturing philosophy centered on standardized precision and chemical stability. The company’s infrastructure is designed to provide consistency for high-volume industrial orders across diverse sectors.

1. Specialized Production Environments and Quality Control The core strength of ACS lies in its controlled manufacturing ecosystem. To serve the electronics and optical sectors, the company operates high-precision coating lines within dust-free cleanrooms. This environment is essential for preventing the inclusion of airborne particulates that can cause microscopic dents or "fish-eyes" in the film.

Precision Coating Control: Utilizing advanced gravure and slot-die coating technologies, the factory achieves uniform adhesive thickness across the entire width of the roll, which is critical for maintaining consistent peel strength.

In-House Physical Testing: ACS maintains dedicated facilities to measure parameters such as 180-degree peel strength, tensile elongation, and Dyne levels, ensuring each product aligns with the technical data sheets required by high-precision manufacturing.

2. Principal Application Scenarios and Functional Use-Cases The functional films engineered at the Foshan facility are utilized in high-stakes environments where surface failure results in significant scrap costs:

Optoelectronic Displays: Protecting polarizers, touch panels, and backlight units (BLU) during the multi-stage assembly of smartphones and tablets.

Automotive Interior Surfaces: Safeguarding high-gloss "piano black" trims, decorative chrome, and infotainment screens from abrasions during vehicle assembly and maritime shipping.

Precision Metal and Glass Processing: Serving as a protective barrier for brushed stainless steel, aluminum sheets, and tempered glass during CNC machining, deep drawing, and chemical etching.

Home Appliance Aesthetics: Providing wear-resistant protection for the exterior panels of premium refrigerators and washing machines, ensuring a residue-free unboxing experience for the end consumer.

3. Bespoke Adhesive Engineering and Material Synergy ACS distinguishes itself through the modulation of adhesive chemistry. By tailoring the molecular weight and cross-linking density of its adhesive systems, the company provides:

Stable Peel Strength: Ensuring that the adhesion level remains constant over time, even when the protected part is stored in high-humidity or high-temperature environments.

Zero-Residue Removal: A critical requirement for optical glass and electronic casings, ACS formulations guarantee that the film can be removed without leaving ghosting shadows or chemical residues.

Anti-Static (ESD) Functionalization: For semiconductor environments, ACS integrates anti-static properties into the PET film to prevent the attraction of dust and protect sensitive circuits from electrostatic discharge.

Conclusion

The evolution of the high-performance film industry requires a convergence of polymer physics, chemical precision, and industrial adaptability. As a professional manufacturer, Foshan AoChuanShun New Material Industrial Co., Ltd. (ACS) continues to redefine the standards for surface protection by prioritizing material performance and mechanical durability. By focusing on the synergy between the PET substrate and advanced adhesive systems, the company provides the essential material security that enables global brands to deliver flawless products. As manufacturing automation continues to accelerate and technical requirements become more exacting, the commitment to precision at ACS ensures that every surface, no matter how sensitive, remains protected throughout its industrial journey.

For additional information regarding technical data sheets, material specifications, or customized inquiries, please visit the official corporate website: https://www.acs-plasfilm.com/

Media Contact

Foshan Ao Chuan Shun New Materials Industry Co., Ltd. daphne@aochuanshun.com http://www.acs-plasfilm.com