Yangzhou, Jiangsu Feb 3, 2026 (Issuewire.com) - The Significance of CE Certification as a Global Benchmark

In the realm of international trade and industrial safety, the CE (Conformité Européenne) mark serves as more than just a regulatory requirement; it is a definitive symbol of quality and technical integrity. For a manufacturer like Mivi, achieving CE certification is a rigorous process that validates the machine’s compliance with essential health, safety, and environmental protection standards set by the European Union. This certification acts as a "technical passport," allowing seamless entry into the European Economic Area and serving as a credible benchmark for customers in North America, Southeast Asia, and the Middle East.

Enhanced Operational Safety: CE standards require comprehensive safety features, including emergency stop mechanisms, protective shielding, and electrical insulation, which significantly reduce the risk of workplace accidents.

Standardized Technical Documentation: The certification process ensures that all technical manuals, circuit diagrams, and operational instructions meet international clarity and accuracy requirements.

Environmental and Electromagnetic Compatibility: Certified machines are tested to ensure they do not emit harmful levels of electromagnetic interference and that their energy consumption patterns align with modern ecological directives.

Global Trust and Risk Mitigation: For international buyers, the CE mark mitigates the risk of importing sub-par machinery, providing assurance that the equipment has undergone independent third-party verification.

As global supply chains become more scrutinized, the presence of such certifications distinguishes professional manufacturers from entry-level workshops, fostering a culture of accountability and continuous improvement within the manufacturing sector.

Mivi: Integrating Expertise with Technical Innovation

Deeply understanding the profound significance of CE standards for enhancing operational safety, standardizing technical documentation, and ensuring environmental compatibility, Miwei has consistently integrated this stringent international standard into its over 20 years of R&D DNA.

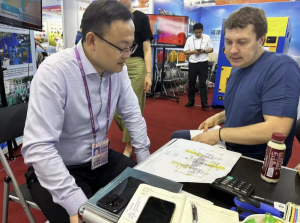

As a China Top Steel Pipe Making Machine Manufacturer, Yangzhou Mivi Machinery Manufacturing Co., Ltd. (Mivi) has emerged as a pivotal player in this space, bridging the gap between traditional heavy machinery and the digital precision required by modern international standards. These machines are not merely tools for production; they are the backbone of industries ranging from automotive exhaust systems and furniture manufacturing to large-scale oil and gas pipelines.

The steel pipe industry is currently navigating a period of rapid technological integration and shifting market dynamics. Historically, pipe production was characterized by high energy consumption and significant material waste. However, contemporary trends point toward a "smart factory" approach, where automation and efficiency are paramount. The rising global investment in urban infrastructure, particularly in developing economies, has created a sustained demand for versatile tube mill lines capable of producing various shapes and sizes—from standard round pipes to complex square and rectangular profiles.

Faced with the urgent demand for "smart factory" models from the global supply chain, Miwei proactively transcends the limitations of traditional manufacturing. By continuously promoting the standardization and precision of its equipment, it has successfully transformed the authority of CE certification into a guarantee of trust from global customers. This not only ensures that every pipe welding machine operates efficiently within the framework of international standards but also signifies that Miwei is leading industry trends responsibly, perfectly integrating the customization flexibility of Chinese manufacturing with internationally recognized industrial safety benchmarks, providing reliable technical support for global infrastructure construction.

Core Advantages and Technical Competencies

Yangzhou Mivi Machinery Manufacturing Co., Ltd. represents the culmination of over 20 years of expertise in the specialized field of tube mill line manufacturing. Operating from a 25,000 m² facility with streamlined logistics, the company has transitioned from a local specialist to an internationally recognized brand. Mivi’s core strength lies in its ability to integrate the development, manufacturing, and sales of tube mills, cold rolling mills, and auxiliary equipment into a unified, client-centric service model.

The company’s competitive edge is best reflected in its commitment to precision engineering and customized solutions. While many manufacturers offer standardized models, Mivi focuses on the specific metallurgical and mechanical requirements of the end product.

The success of Mivi’s equipment in the global market can be attributed to several key technical and structural advantages:

Advanced High-Frequency Welding Technology: Mivi machines utilize optimized welding systems that ensure a stable and narrow heat-affected zone, resulting in stronger seams and higher-quality finished pipes.

Precision Roller Design: The use of high-grade materials for rollers ensures longevity and reduces the frequency of maintenance, which is critical for continuous production environments.

User-Centric Automation: The integration of PLC (Programmable Logic Controller) systems allows operators to monitor every stage of the forming and sizing process, ensuring consistency across different batches.

Comprehensive Export Experience: With two decades of international trade history, the company understands the nuances of global shipping, installation, and after-sales support, ensuring that technical assistance is available regardless of the geographic location.

Application Scenarios and Client Success

The versatility of Mivi’s steel pipe-making machines allows them to serve a diverse range of applications. In the automotive sector, these machines produce the high-strength tubing required for chassis and exhaust components. In the construction industry, they are used to manufacture structural hollow sections that support modern architectural designs. Past projects have seen Mivi equipment deployed in various international industrial parks, where they have been praised for their ability to handle different material grades, including carbon steel and stainless steel, with minimal changeover time.

By focusing on the "Total Cost of Ownership," Mivi ensures that its clients receive a machine that is not only competitively priced but also durable and easy to maintain. This philosophy has earned the company a reputation for reliability, evidenced by a growing portfolio of repeat customers who rely on Mivi to scale their production capabilities.

Conclusion

As the global demand for high-quality steel tubing continues to rise, the role of experienced manufacturers becomes increasingly vital. Yangzhou Mivi Machinery Manufacturing Co., Ltd. stands at the intersection of traditional manufacturing excellence and modern quality standards. By prioritizing CE-certified quality and investing in continuous technical innovation, Mivi is setting a new standard for what a China Top Steel Pipe Making Machine Manufacturer should represent in the 21st century. Whether for industrial, commercial, or specialized applications, the commitment to precision and safety remains the hallmark of their contribution to the global industrial landscape.

For more information regarding technical specifications and product offerings, please visit the official website: https://www.mivimachine.com/

Media Contact

Yangzhou Mivi Machinery Manufacturing mivi@mivigroup.com