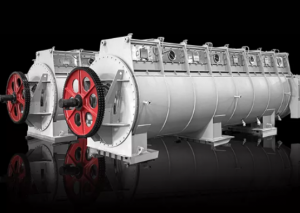

Zhuhai, Guangdong Feb 4, 2026 (Issuewire.com) - APEX MACHINERY & EQUIPMENT CO., LTD, a premier provider of industrial waste management solutions, is pleased to announce its strategic expansion into new international markets. This growth reinforces its standing as a specialized Customized Disc Dryer Manufacturer With Mitsubishi Technology, offering advanced thermal processing equipment designed for the most demanding industrial environments. The company’s signature SDK and FDK series disc dryers utilize an indirect heating method through a central hollow shaft and multiple hollow discs. This sophisticated design ensures a high heat transfer coefficient and a large effective heating area relative to the equipment’s footprint. Capable of continuous operation for up to 8,000 hours annually, these systems are engineered to handle varying moisture levels in materials such as municipal sludge, chemical residues, and hazardous waste while ensuring minimal secondary pollution and a low-oxygen safety environment.

The Global Trajectory of Waste Treatment and Environmental Protection

The international industrial landscape is currently navigating a period of rapid evolution regarding environmental stewardship and resource recovery. As regulatory frameworks tighten across Europe, North America, and Southeast Asia, industrial entities are under increasing pressure to adopt technologies that prioritize the "three Rs": reduction, recycling, and reuse. The global environmental protection machinery industry is no longer just a niche sector but a cornerstone of modern manufacturing and urban planning.

Market data suggests that the transition toward a circular economy is driving a significant surge in the demand for thermal drying technologies. In the past, sludge disposal relied heavily on landfilling or agricultural use; however, these methods are being phased out due to land scarcity and the potential for heavy metal or pathogen contamination. Modern industrial standards now dictate that sludge must be rendered "harmless" and "stable" before final disposal. This has shifted the focus toward high-efficiency drying systems that can reduce the volume of waste by up to 80%, significantly lowering transportation and disposal costs.

Furthermore, the rise of "Waste-to-Energy" initiatives is a major trend influencing the industry. Dried sludge and industrial residues often possess significant calorific value, allowing them to be utilized as auxiliary fuel in cement kilns or coal-fired power plants. This synergy between waste management and energy production is creating a vast market for manufacturers who can produce equipment that maintains consistent output quality. Additionally, the industry is seeing a move toward integrated systems where waste heat from other manufacturing processes is captured and used as the primary thermal source for drying, further optimizing the carbon footprint of industrial facilities.

Technological Leadership and Customization Capabilities

Since its establishment in 2004 in Zhuhai, China, APEX MACHINERY & EQUIPMENT CO., LTD has focused on bridging the gap between high-end engineering and practical ecological needs. A primary driver of the company’s success is its role as a customized manufacturer. Unlike off-the-shelf solutions, each disc dryer is tailored to the specific physical and chemical properties of the material it will process. This customization extends to the choice of materials for the stator and rotor, the configuration of the scrapers, and the integration of auxiliary systems such as scrubbers and condensers.

The core technology of the disc dryer involves a horizontal cylindrical stator with a dome-shaped upper section that serves as a collection point for carrier gases and evaporated moisture. Inside, a rotor consisting of a hollow shaft and vertically mounted hollow discs facilitates the movement of the material. The heating medium—typically steam or thermal oil—circulates through the shaft and discs, ensuring that the material is heated indirectly. This prevents the degradation of heat-sensitive materials and reduces the volume of exhaust gas that must be treated. The inclusion of specialized propellers on the disc edges ensures that the material is constantly stirred and pushed forward, preventing the "glue phase" sticking that often plagues traditional drying equipment.

Quality assurance remains a non-negotiable priority for the organization. By maintaining advanced laboratory facilities and a dedicated team of technical analysts, the company ensures that every piece of equipment undergoes rigorous testing for thermal efficiency and structural integrity. The adherence to international quality management standards and the acquisition of numerous technical patents have solidified the company's reputation as a reliable partner in the global supply chain.

Core Product Portfolio and Industrial Applications

The product range at APEX MACHINERY is designed to address the comprehensive lifecycle of industrial waste. The company’s offerings are categorized into several key areas to meet diverse market demands:

Disc Drying Systems: These are the flagship products, utilized primarily for the thermal reduction of materials. Beyond standard municipal and industrial sludge, these systems are highly effective for drying gypsum, fish meal, pharmaceutical residues, and kitchen biogas residue. The ability to switch between semi-drying (reducing moisture to approximately 40%) and full-drying (reducing moisture to below 10%) provides operators with maximum flexibility.

Conveying Systems: Recognizing that the movement of high-viscosity or abrasive materials is a major challenge in waste treatment, the company provides robust conveying solutions. These systems are essential in the thermal power, metallurgy, and port logistics sectors, where the stable transport of materials is critical to maintaining production uptime.

Wastewater and Leachate Treatment: The company’s 3D electrocatalytic oxidation equipment represents the cutting edge of wastewater treatment. These systems are specifically designed to treat high-salinity and high-toxicity wastewater, such as landfill leachate and pharmaceutical effluent, which traditional biological treatments cannot handle effectively.

Success Stories: Empowering Global Industrial Projects

The practical impact of these technologies is best illustrated through a series of diverse project implementations. In the municipal sector, the Jies and Huachuan Sludge Drying Projects stand as benchmarks for high-volume treatment, where the disc dryers have successfully managed large-scale urban waste streams with high reliability. Similarly, the Hefei Sludge Drying Project has demonstrated the equipment's ability to maintain performance in a high-demand, continuous-use environment.

Beyond sludge, the company has excelled in specialized material drying. The Chiping Gypsum Drying Project utilized customized thermal profiles to process industrial byproducts for the building materials industry, while the Fuzhou Kitchen Biogas Residue Drying Project showcased the versatility of the disc dryer in the emerging biomass and organic waste sector. In the realm of logistics and material handling, the Beijing Environmental Protection XGZ50 project and the Fujian Longjing Environmental Protection Hongrun Petrochemical project have proven the durability of the company’s conveying systems under heavy-duty conditions.

Conclusion

As global industries face the dual challenge of increasing waste volumes and stricter environmental mandates, the necessity for efficient, specialized drying technology has never been greater. APEX MACHINERY & EQUIPMENT CO., LTD is committed to addressing these challenges by delivering high-performance, customized solutions that prioritize thermal efficiency, operational safety, and long-term durability. By focusing on technical innovation and customer-centric design, the company is not only expanding its global reach but also contributing to the sustainable development of the industries it serves. Through its role as a dedicated manufacturer and technical partner, APEX MACHINERY continues to drive the advancement of environmental protection technology on a global scale.

For further information regarding product specifications, technical data, or to request a consultation for customized environmental machinery, please visit the official company website: https://www.apexecoequip.com/index.html

Media Contact

APEX MACHINERY & EQUIPMENT CO., LTD postmaster@apexmeco.com https://www.apexecoequip.com/